Advanced Two Shot Injection Molding Process | A Guide

Innovation Ultimate Guide to Two-Shot Injection Molding Process

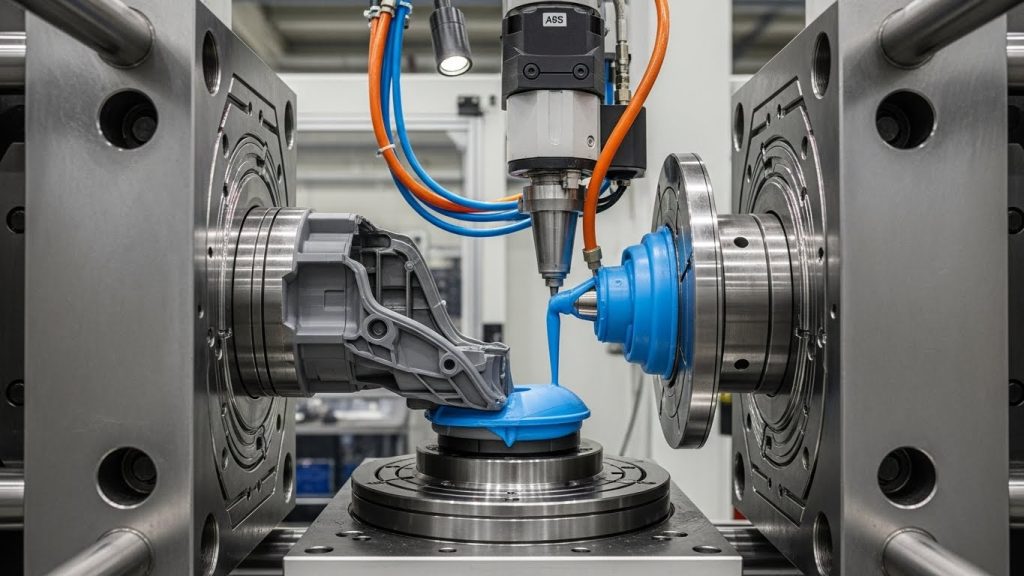

The two-shot injection molding process, also 2K injection molding or dual-shot injection molding, has transformed modern manufacturing processes since it allows multi-material parts to be produced in one continuous and smooth manufacturing process. This is an innovative method compared to the traditional molding technique, and the manufacturers can now bring soft-touch materials in combination with rigid plastics, thus generating parts that are functional as well as pleasing to the eye. The leader in this technology is the professional 2K injection molding company known as SunOn, which provides high-precision two-shot molded components to the automotive, medical, electronic, and consumer sectors.

What is the Two-Shot Injection Molding Process?

Two-shot injection molding process: This is whereby two different materials or colors of the same mold are injected into the same mold in succession. The result of this process is integrated components that are not accumulated in hard and soft materials; thus, they do not have to undergo post-production assembly. Traditional methods are core-back two-shot molding, rotary platen two-shot molding, and in-mold assembly molding, which provide a high level of dimensional accuracy and a high level of adhesion strength between materials.

Key Features:

- Two-shot sequential injection process.

- The combined molding process needs to be efficient.

- Hard-soft material bonding

- Optimization of cycle time in high-volume production.

Two-Shot Molding Technology Advantages

There are many benefits associated with investing in dual-shot injection molding:

Functionality of Product - Use soft-touch TPE or TPU with hard plastics such as ABS or PC.

Aesthetic Flexibility - Design two-color branding and ergonomic designs.

Cost Efficiency - Cut labor and assembly expenses through one-cycle multi-material part molding.

High Accuracy - Tight Tolerance Molding: Complex geometries.

Durability - Achieve excellent adhesion strength of dissimilar materials.

Raw Materials of Two-Shot Injection Molding

The materials that are chosen are of vital importance in performance. SunOn uses a range of elastomers and thermoplastics to satisfy the needs of various industries:

- Plastic soft-touch and flexible components(thermoplastic elastomer) TPE/TPU.

- Plastics with engineering grades of ABS, PC, and polyurethane (PU).

- Overmolding of silicone, medical, or high-performance.

- Ergonomic designs in hard-soft materials.

With these materials, the manufacturing of automotive interior parts, consumer electronics enclosures, medical apparatus parts, and industrial assembly can be made more functional.

Uses of Two-Shot Injection Molding

Many industries make use of the multi-material injection molding process:

Automotive

- Soft-touch grips and handles

- Dashboard panels and trims

- Door handles and seals

Electronics

- Keypads and buttons

- IP cases and smart watch cases.

- Protective casings

Medical

- Ergonomic surgical tools

- Housing of medical instruments.

- Casing of devices.

Consumer Products

- Appliance handles

- Ergonomic kitchenware

- Long-lasting home appliances.

SunOn provides parts with precision, along with two-shot molding coupled with a multi-material adhesion process, resulting in functional parts that are also aesthetically appealing.

Optimization of Process in Two-Shot Injection

Optimization of processes used in efficient two-shot injection molding includes:

- Material flow in sequential injection.

- High volume production, Multi-cavity two-shot molds.

- Optimization of cycle time to minimize the costs of production.

- Extremely fine tooling to give tight tolerances.

SunOn has the most modern CNC machining, EDM, and polishing equipment, which enables them to maintain a uniform quality in every production batch.

Injection Molding Two-Shot Custom

SunOn offers one-stop services to customers who require two-shot injection molding services. Their offerings include:

- OEM Two-shot injection molding solutions.

- Two-shot injection molding, fully service.

- Design to production items.

- Dual-material component contract manufacturing.

Through the combination of design, prototyping, and mass production, SunOn provides a high-quality outcome, cost-effectiveness, and prompt market preparation.

Quality Assurance and Industry-Leading Excellence

The professional 2K injection molding company of SunOn has strong quality control, automated molding solutions, and full-service testing. This guarantees:

- Complex geometric dimensional accuracy.

- The bonding of hard and soft materials is seamless.

- Mass production without loss of quality.

Their two-shot molding is very precise and, therefore, reliable and functional as well as visually perfect, which is important in automotive, medical, and consumer electronics industries.

What are the Advantages of SunOn Two-Shot Injection Molding?

SunOn is a blend of technical innovation, materials expertise, and service excellence. The major points of difference are:

- Highly advanced two-shot injection molding facilities.

- Multi-material parts molding is integrated.

- Application-specific solutions that can be customized.

International Assistance and Services to OEM

SunOn provides affordable and quality solutions, whether you require dual-material automotive parts, consumer products of an ergonomic nature, or even medical device housings.

Conclusion

The two-shot injection molding process is the future of precision multi-material manufacturing. With the help of the dual-shot injection, bonding of hard and soft materials, and optimization of the process, the companies can create innovative and durable, and aesthetically pleasing components with less labor, but at high efficiency.

The professional 2K injection molding services offered by SunOn render them the manufacturer of choice to OEMs and industrial customers with turnkey solutions, high precision parts, and custom multi-material solutions.