Research-Grade Silicone Compression Molding | A Innovation

Understanding Compression Silicones for Research Purposes

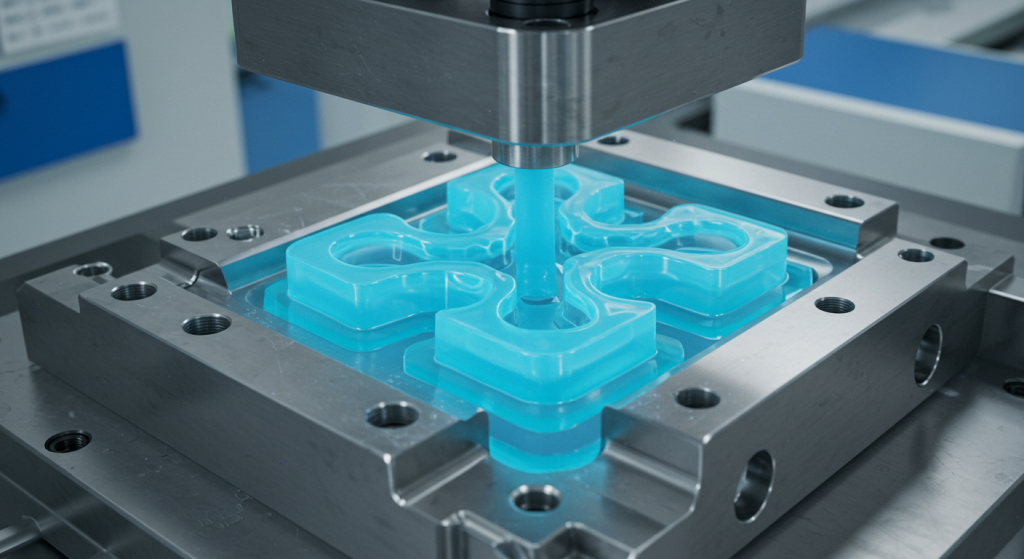

- As part of compression, production of custom silicone components for laboratory, biomedical, and industrial grade components using silicone elastomers of utmost precision and performance is conducted. This methodology is premium as it achieves an advanced level of complexity with each unit geometrically different, and remains consistent for mass production.

- The period of time during which silicone is placed eternally folded in molds is assisted by custom-made molds, whereby the silicone is etched geometrically, and the silicone is placed in an outer compartment. This method is referred to as silicone compression molding and is given the Research-Grade Silicone Compression Molding. It is touted for its ability to preserve intricate details and is thereby perfect for silicone components of unmatched precision.

Key Benefits of Silicone Compression Molding

An increased consumer base for silicone compression molding in the context of research and industrial use is associated with an increased number of benefits received from its application.

- Precision and Accuracy

The level of dimensional tolerances achieved, from ±0.2mm to ±0.5mm depending on the complexity of the part, is achieved by the Research-Grade Silicone Compression Molding method. This remains important for laboratory equipment components and biomedical silicone parts. Even the slightest changes in geometry can lead to unachievable performance, which is the goal for advanced preservation technologies.

- Tailored Shapes and Sizes

Just like the small seals and the large industrial components silicone compression molding has, silicone components can also be customized and designed with different shapes and sizes.

- Increased Volume Production

Lack of quality will not be an issue, as multi-cavity molds are able to use compression molding silicone to mass produce an unlimited supply of silicone molded parts, silicones needed for research, industrial purposes, and so on.

- Flexible Material Selection

High-purity silicone and biocompatible silicones are two of the many silicone elastomers that can be used for experimental purposes. Therefore, the silicone materials used for silicone compression and lab purposes are also silicone elastomers.

- Price Efficiency

Saving on tooling costs, silicone compression molding also produces cost-efficient, durable silicone elastomers with mechanical and chemical resistance.

- Increased Design Freedom

Research-grade silicone compression parts, along with multi-component silicone molding, can be used for scientific research purposes, and materials needed for lab testing are silicone formed from the rest of the parts.

Silicone Grades and Their Applications

The following are grades of silicone together with the use of each that are pertinent to silicone compression of research grade:

• Medical Grade Silicone: Used in laboratory-grade apparatus, medical devices, and experimental silicone kits, this silicone has biocompatibility as well as resistance to sterilization, making it ideal for biomedically related applications.

• Industrial Silicone: Used in the automotive, consumer products, and electronics markets. The silicone compression components for these applications are high-performance and provide chemical and heat resistance as well as durability for sustained operation.

• High Purity Silicone: This grade of silicone is necessary for certain components as it has the lowest risk of contamination and is more suitable for precision silicone compression.

Research Grade Silicone Compression Processes and Techniques

The silicone compression molding process is designed for high precision, repeatability, and high-volume production. These include:

• Precision Silicone Molding: Producing components with high Dimensional stability and tight tolerances.

• Low Shrinkage Silicone Molding: To decrease material deformation and replicate silicone materials in experimental devices.

• Multi-Component Silicone Molding: This pertains to parts that have dual or more materials, helpful with intricate components in research-grade silicone compression molding.

• Custom Silicone Fabrication: Meets performance and functional standards in laboratory and factory settings.

Applications of Research-Grade Silicone Compression

1. Science Research and Laboratory Applications

In laboratory equipment, experimental kits, and precision testing materials, silicone compression parts and components are used. In addition, there is a great need for silicone components capable of withstanding rigorous scientific procedures. Such procedures demand silicone components with extreme precision. Due to their durability, silicone components are highly sought after.

2. Biomedical Applications and Medical Devices

Medical silicone compression is important for medical and biomedical purposes. It is strongly recommended because of its compatibility with the body, its resistance to being sterilized, and its applicability to prosthetics, seals, and components of laboratory devices.

3. Industrial and Consumer Goods

Silicone elastomers are used in automotive parts, electronic appliances, and household appliances. Their heat resistance, flexibility, and chemical resistance make them durable. Besides, apart from the aforementioned appliances, silicone elastomers are also used in many other devices as they seamlessly integrate into very complex assemblies.

4. Contract R&D and In-House Prototype Testing

Research-grade silicone parts help in testing new designs. Also, silicone compression helps in the rapid prototyping of silicone components. This flexibility helps in experimental setups as well as scientific applications.

Why Opt for Custom Silicone Compression Solutions?

Research-grade compression molding focuses on and adapts to the underlying principles of silicone component fabrication. By aligning silicone pieces to specific intended functions, a manufacturer is assured of:

• Optimum utilization of the component to counteract heat, chemicals, and mechanical work.

• Prolonged component life with dependable performance in experimental or industrial setups.

• Accurate reproduction of intricate shapes from low-shrink silicone molding.

• Scalable production from prototype to mass manufacturing.

Conclusion

Research-grade silicone compression molding is an essential technology for creating silicone components used in research, medical, and industrial applications. Combining high-purity silicone, medical-grade elastomers, and precision silicone compression components, this process ensures accuracy, durability, and flexibility. By understanding technical specifications, material choices, and advanced molding techniques, optimal performance and consistent integration can be achieved across laboratory equipment, biomedical devices, and industrial components. To discover tailored silicone solutions, consult SunOn Mould to witness the future of silicone manufacturing.