Overmold Mold Maker | Custom & High-Precision Solutions

What is Overmolding, and What is its High Demand?

In overmolding, a rigid substrate or an already molded part is molded with a material that is generally a soft elastomer. This enables the manufacturers to make parts that are more grip, vibration-dampening, insulated, sealing, and comfortable parts without necessarily manual assembly.

A skilled overmold maker of molds will guarantee flawless adhesion between the two materials, eliminate interface shortcomings, and provide components that will feel elegant and strong.

It is used in:

- Electronics housings made of overmolded materials.

- Plastic components with soft grips.

- Overmolding of wire and connectors.

- Automotive overmold parts

- Sealed overmold components

- Medical device overmolding

Overmolding improves the performance of products, their feel, and their longevity, such as ergonomic toothbrush handles, strong automotive connectors, and many others.

Why is Selecting the Correct Overmold Maker of Molds Important?

The skill, technology, and engineering knowledge that your overmold mold maker has is directly related to the quality of your overmolded product. There is a fine balancing of temperature, pressure, bonding force, and shrinkage actions during overmolding, and therefore design of the moulds is highly technical.

An effective injection overmold manufacturer ensures:

- Top interface bonding (soft material + hard substrate)

- Zero delamination

- Proper compatibility of materials.

- Dimensional stability

- High tolerance control

- Extended mold life

- Shorter cycle times

- High-quality aesthetics of products.

This is the reason why collaborating with a professional overmold mold maker, such as SunOn, transforms the whole manufacturing process.

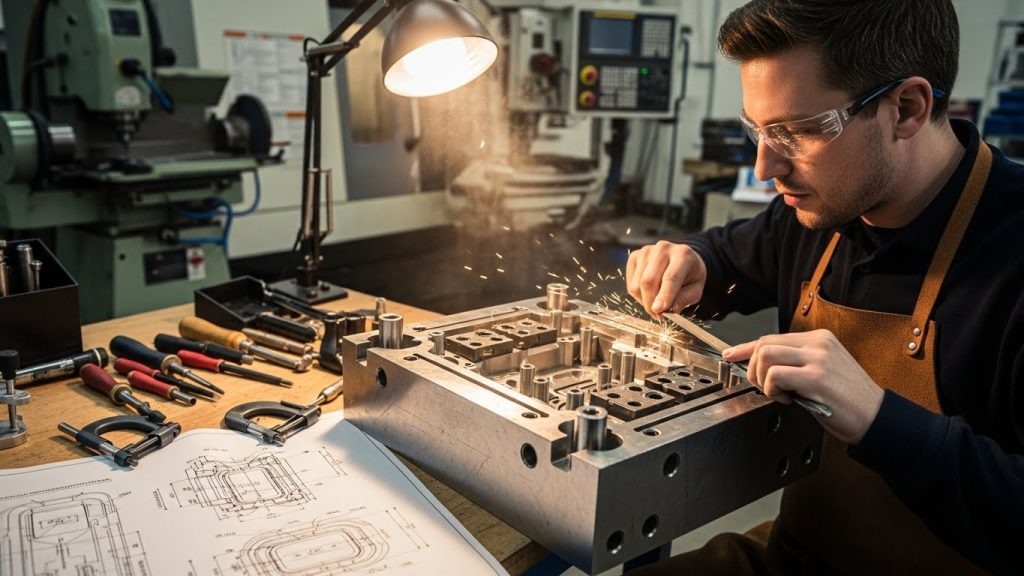

SunOn: The Superior Molder of Molding and Overmold Tooling

Over the decades, SunOn has been providing precision-engineered molds that redefine quality and reliability. Being known worldwide as one of the manufacturers of the overmold tooling, SunOn is focused on innovation, stability, and excellence.

Why SunOn Leads the Market:

- State-of-the-art CNC mould production facilities.

- Fabricating EDM tools of the future.

- Advanced overmolding mold flow analysis.

- Professional engineering in high-accuracy mold making.

- Plastic, elastomers, and hybrid knowledge in materials.

- Rapid tooling & prototyping

- OEM/ODM ability of overmolding tools.

- Complete service injection molding.

All the molds are prepared with passion, skills, and dedication to world-standard practices.

Learning the Overmolding Mold Design Process

An overmold of high quality demands a high level of structural engineering. There are dozens of important decisions during the design stage: the positioning of gates, balancing of runners, cooling scheme, and the choice of steel. The most significant design considerations utilized by the most successful custom overmold mold maker are as follows:

1. Overmolding Mold Flow Analysis.

Through superior software simulations, engineers visualize:

- Melt flow behavior

- Material viscosity

- Weld line locations

- Air trap zones

- Bonding interface dynamics

This gets away with the defects before the construction of the mold.

2. Gate Design Optimization

The correct position of the gates is necessary to make sure they achieve:

- Uniform material flow

- Reduced shear stress

- Balanced filling

- Increased sticking ability of materials.

The engineering team of SunOn relies on data-based approaches to optimize the geometry of gates on a project-by-project basis.

3. Runner System Engineering

A powerful runner construction minimizes pressure loss and enhances the strength of bonds.

- Cold runner

- Hot runner

- Hybrid runner systems

This action has a radical impact on the shaping of efficiency and cost.

4. Mold Steel Selection (H13, S136, P20)

The grade of steel defines the longevity of moulds and performance.

Typical choices include:

- H13 - Hard, best use with abrasive material.

- S136 - Excellent corrosion-resistant features.

- P20 - general-purpose molds

This technical peculiarity influences the process of shrinkage and heat dissipation.

5. Channel Optimization by Cooling

Properly designed cooling channels have minimized cycle time and facilitated dimensional stability.

SunOn integrates:

- Conformal cooling

- Baffle cooling

- The circuits are high-efficiency coolant.

Optimization of cycle time boosts production.

6. Ejection System Design

The ability to eject without scratching, deformation, or stress marks.

SunOn mixes:

- Pin ejectors

- Blade ejectors

- Sleeve ejectors

- Air ejector systems

Unplanned Overmold Mold Maker Services at SunOn

You are in the market to find a custom mold maker. SunOn provides complete service, tooling, and manufacturing solutions that suit your product requirements.

Their capabilities include:

- Custom overmolding tooling

- Insert overmolding fabrication of molds.

- Skills in a two-shot overmolding mold maker.

- Mold maker services for multi-materials.

- Solutions for a rubber overmold maker.

- Low-volume overmold mold manufacturer alternatives.

- Crafting and production of overmold using industries.

- Maker of high precision services -insert overmolding molds.

Since all projects are of a unique nature, SunOn engineers work hand-in-hand with the clients to develop molds that are impressive.

Applications with High-Precision Overmolding Requirement

The best industries are based on overmolding manufacturing services, which include:

Medical Industry

- Surgical grips

- Diagnostic devices

- Bio-safe elastomeric surfaces.

Electronics

- Over-stamped electronic boxes.

- Protective casings

- Waterproof connectors

Automotive

- Anti-vibration components

- Switch housings

- Sealed connectors

Consumer Goods

- Tools

- Kitchenware

- Power tool grips

Industrial Solutions

- Shock-resistant overmolding

- Heavy-duty components

- Multi-layered housing enclosures.

SunOn is a manufacturer with diverse knowledge, and it helps all these sectors with accuracy and effectiveness.

Full-Service Manufacturing Competence of SunOn

We Offer:

- Injection molding in the professional sphere.

- High-volume production

- Tight-tolerance molding

- Good quality management in each process.

- Post-processing & assembly

This not only qualifies SunOn as a mold maker, but also a whole manufacturing partner.

The Reason SunOn is the Best Overmold Mold Maker

The reputation of SunOn is based on:

- Unmatched precision

- Professional engineering

- Innovative tooling technology.

- Quality materials

- Consistent delivery

- Customers-long-term partnerships.

All the molds are designed with great attention and expertise of the master engineers who know the fine art of heating, pressure, flow, and bonding. It is a high-endurance molding factory, a trusted vendor of overmold tools, and a global leader in excellence.

Conclusion:

When you need the finest overmold mold producer, the team that comprehends the art of mold engineering, and the partner that takes your products as seriously as they should be, you need not go further than SunOn. Overmold tooling solutions to multi-material mold design, prototype to full-scale production, SunOn has the solution to your successful, reliable, and innovative overmolding.