Optically Clear Silicone Compression Molding | Silicone Parts

What is Optically Clear Silicone Compression Molding?

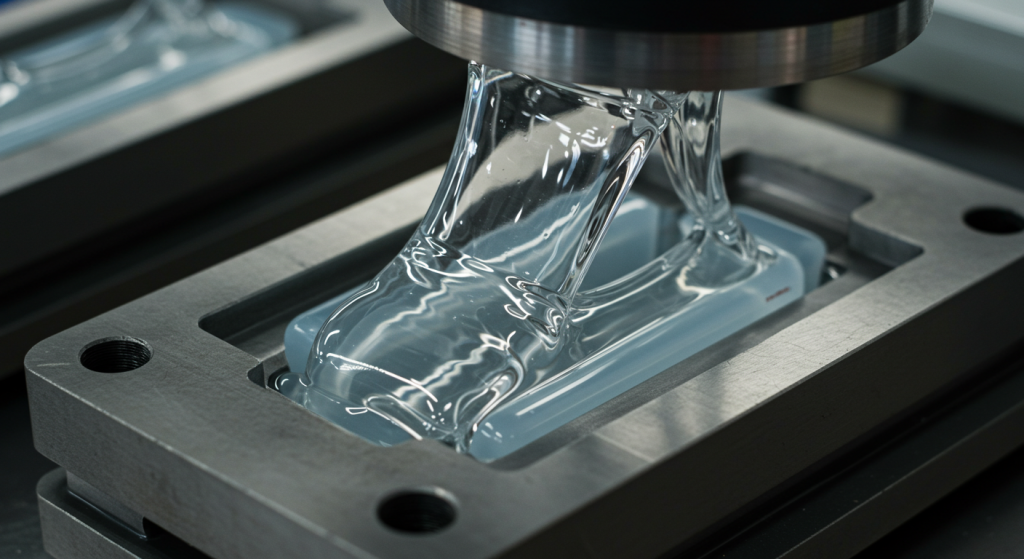

The manufacturing process involved is optically clear silicone compression molding. It utilizes silicone elastomer of the highest clarity to manufacture transparent silicone components that possess unmatched optical attributes. Silicone materials are added to molds and then cured under heat and pressure to yield the final product. Optically clear compression molding is better than the other molding techniques because it can be used for more advanced light application devices, such as light lenses, LED silicone components, or even devices used in the medical and laboratory optical fields.

Key Advantages:

• Granular Transparent Optics: The optical clarity in silicone components is clear and unblemished.

• Unmatched Accuracy: Provides optical silicone molded parts aligned to tolerances of ±0.2mm to ±0.5mm, which are crucial for silicone optics precision.

• Freedom of Design: Accommodates intricate shapes and sophisticated optical multi-component molds.

• Sturdy Construction: Provides unblemished silicone that is dimensionally stable, mechanically robust, and immune to thermal cycling.

• Significant Production Volume: Efficient mass production is templatized using multi-cavity molds.

Defining Solutions for Advanced Use Cases

- In line with the complexity of today's era, optically clear silicone compression molding serves as one of the ways to manufacture high-quality, transparent silicone parts owing to its unique capabilities. Engineers or manufacturers can utilize the technique to form precision optical silicone molded parts, transparent silicone compression parts, and even unique custom clear silicone compression solutions to match the needs of the industry.

- Components of the product are manufactured using high-purity optically clear silicone and biocompatible clear silicone, and optical-grade silicone, which ensures that the product has dimensional stability, clarity, and resistance to heat and chemicals.

Advantages of Optically Clear Silicone Compression Molding

1. Striking Optical Clarity

For LED and lighting silicone components, optical lenses, and display systems, there is a strong requirement for silicone of the highest optical clarity. Compression molding keeps silicone clear and uniform without discoloration and other silicone-shifting imperfections. Compression molding systems that operate with low-discoloration silicone will always ensure that optical performance across all components manufactured is of the same level.

2. Flexibility with Materials

The system can support many types of silicone elastomers, such as:

High clarity silicone elastomers for optical clear components

• Clear medical biocompatible Silicone for medical and lab usage

• Clear silicone for electronics and other high-temperature operations

• Transparent silicone parts for industrial chemical applications

3. Customization and Accuracy

The molds for Custom Compression Clear silicone can produce a range from low-shrinkage clear silicone to complex MCAD shapes with Optically Clear Silicone Multipoint Molding, fulfilling even the most challenging technical requirements for the lenses, components, and prototypes developed for optical R&D.

4. Cost-Effective Production

They say "the tool makes the man", and with compression molding of clear silicone, this quote rings true. It has significantly lower tooling costs and produces high-quality output. It also allows the utilization of multi-cavity tooling, which allows high-volume production of the optically clear silicone compression-molded parts. These multi-cavity molds also guarantee continuous production of the components while preserving dimensional stability and optical performance.

5. Durability and Performance

Optically clear silicone compression-molded parts have the following characteristics:

• Flexible and resilient optically clear silicone

• Heat-resistant transparent silicone

• Dimensionally stable, clear silicone

• Chemical-resistant optical silicone

All these properties combined make it ideal to be used for long-term use in heavy industrial projects, medical use, and for consumer products.

Process and Techniques

The compression molding process used for these optically clear applications includes several stages, which include:

1. Material Preparation

Preparation of the silicone elastomer components should include special attention to the components' clarity and purity. It is ideal to start with high-purity optically clear silicone to achieve minimal discoloration and an ideal optimized light performance transmission.

2. Mold Filling

The compression molding process for transparent silicone, in this case, should be able to achieve complete cavity filling. This ensures smooth, defect-free surfaces for the molded components.

3. Curing and Compression

The molds undergo heat and pressure treatment, which allows the spacing of the molds to be filled both optically and dimensionally. Non-clear fillers also undergo this process to allow the components to achieve flexibility.

4. Demolding and Finishing

Once cured, the sections are detached and may require the edges to be trimmed. Post-processing may involve custom-fabricated clear silicone compression to optically tune the elastomer and support high-performance light passage.

Uses

1. Optical Lenses and Components

For LED lenses, camera lenses, and optics peripherals, silicone elastomers possess high clarity. Through compression molding, elements can be shaped accurately to maintain optical performance and low light distortion.

2. Medical and Laboratory Devices

Used biocompatible, optically clear silicone compression molded in medical tubing, laboratory optical devices, and transparent seals. These components comply with the core conditions of transparency, sterility, and chemical resistance.

3. Electronics and Lighting

R&D LED silicone and silicon molded with transparent compression are strong, heat-proof, and stable to chemicals. The process gives custom optical designs that improve the light distribution and overall performance.

4. Industrial and Consumer Goods

In sealing industrial devices and high-performance machinery, clear silicone molded parts are used. With multi-component molds, complex optical parts can be produced for precise consumer electronic devices.

Technical Specification

The optically clear silicone compression molding is flexible and precise:

• Volume Production: High-volume production with multi-cavity molds

• Material Selection: Medical grade, industrial grade, and high-purity clear silicone

• Tooling Cost: The lowest in comparison to other molding operations

• Durability: Flexible, heat and chemical-resistant

• Custom Shapes: Designed in forms of small gaskets to large optical components

• Tolerance Range: ±0.2mm to ±0.5mm depending on complexity

These make it great for multi-component optically clear silicone molded parts, precise optical prototypes, and transparent seals.

Conclusion

Optically clear silicone compression molding offers high precision, wide-ranging use, and affordability. Incorporating high clarity silicone elastomer with optically clear silicone and biocompatible silicone results in strong, dimensionally stable, and translucent parts, which makes it suitable for use in the medical, automotive, electronics, and industrial fields. If you are looking for precision optically clear silicone molded parts as well as tailored services, visit SunOn Mould and browse our extensive inventory featuring optically clear silicone parts, transparent silicone seals, and multi-cavity silicone molds.