Multi-Cavity Injection Mould | High-Precision Plastic Molds

Knowledge on Multi-Cavity Injection Moulds

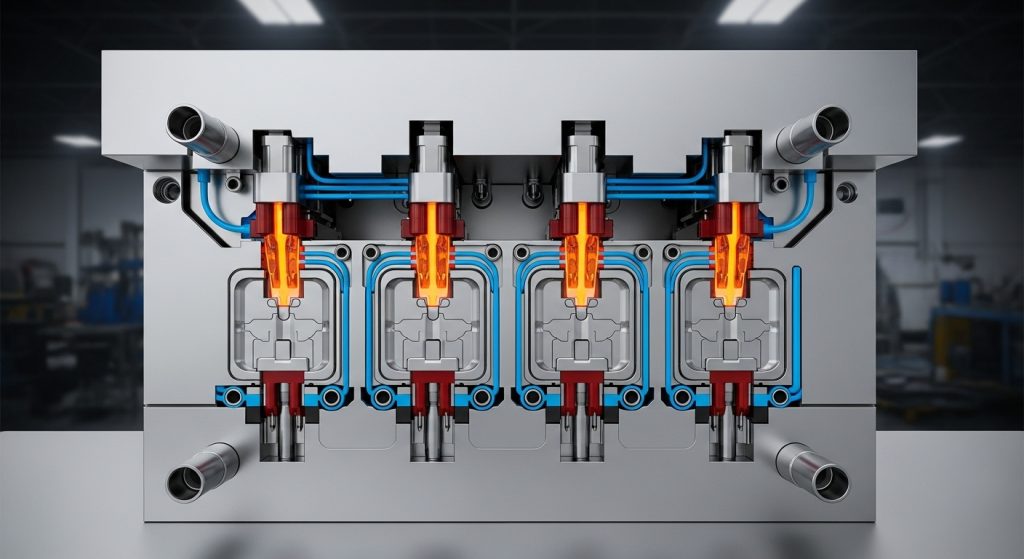

A multi-cavity injection mould is a tool where one can make more than one part in one injection molding cycle. Multi-cavity molds can also be used to manufacture several parts at once, unlike the single-cavity mold, and so they are suited to high-volume plastic processing and saving on total manufacturing expenses.

Key Benefits Include:

- Molds with high efficiency reduce cycle time.

- Stability in the dimensions of the molds.

- Better quality management of injection molding.

- Reduction in costs in tooling and the use of materials.

Visit Sunon Mould to get expert services in the fabrication and design of multi-cavity moulds.

Materials and Construction

Plastic injection moulds are mostly designed out of high-grade steel or aluminum, which is selected due to the strength, heat resistance, and capability to endure recurring cycles. Manufacturers can use:

- Most high-volume production thermoplastics.

- heat- or chemically-resistant parts baked plastics heat-resistant or chemically-resistant plastics

- Automotive, electronic, or medical specialist engineering-grade plastics.

The construction guarantees high-precision moulding, fantastic multi-part overall part replication, and long-lasting, durable multiple cavity moulds.

Design Rules of Multi-Cavity Molds

Multi-cavity injection mold making is also very dependent on careful design. Sophisticated methods of mold design:

- Balancing of the cavity of the mould to fill all the cavities.

- Optimization of the cooling system to minimize cycle time and eliminate warping.

- True geometry and simulation Development 3D CAD mould design.

- CNC machining of short-run tooling.

- Quick prototyping and low-volume production.

Effective design ensures that injection molds are highly efficient, that the production of plastic parts is consistent, and that there is low waste.

Industries: Uses

Multi-cavity injection moulds are utilized in many different industries:

Automotive Industry

Between dashboards and engine parts, automotive components demand large quantities of plastic parts that are accurate. The multi-cavity industrial molds allow manufacturers to manufacture identical parts in large quantities, and these parts are within high tolerance standards.

Consumer Electronics

Electronic housing centers that are highly complex require an injection mold of plastic material that is precise. Multi-cavity technology involves the production of identical components, which makes it less time-consuming as post-production alterations would be minimized, and assembly will be more efficient.

Medical Devices

High-dimensional precision in injection molding is necessary in medical-grade plastics. Multi-cavity plastic molds used to manufacture medical parts enable the company to manufacture many products at the same time without compromising quality and standard measures.

Consumer Goods

Multi-cavity plastic prototyping is used in the production of products like kitchenware, toys, and packaging. This factor of speed, accuracy, and efficiency is what makes manufacturers satisfy the market without affecting quality.

The Benefits of Multi-Cavity Injection Moulds

High-Volume Production

Multi-cavity molds enable several parts to be produced simultaneously so that the manufacturing time and the cost per unit are drastically shortened.

Repeatability and Precision

The precision injection moulds are important in ensuring uniformity of all parts, which are crucial in other industries such as the automotive and electronics industries.

Cost Efficiency

Multi-cavity tooling can prove to be very economical in the long run, though it might be more expensive than single-cavity tooling.

Versatility

Multi-cavity molding can be used in small-scale prototyping with multi-cavity molds, but also in large-scale production of complex geometries and engineering-grade plastic parts.

Reduced Waste

Balancing techniques of the injection molding process and mold cavity optimize the waste of material and failed parts.

Technical Insights

Cycle Time Optimization

An ideal multi-cavity mold will have an effective system of mold cooling and ejection, which is critical to the minimization of cycle time and maximization of general production efficiency.

Tolerance Control

In precision plastic injection tools, the manufacturer is able to achieve tolerances of +-0.1mm to +-0.5mm, depending on the complexity of the part.

Automation Integration

Multi-cavity molds today can be used in an automated injection molding machine, increasing the pace of production and minimizing human error.

Tooling and Maintenance

Mold design and CNC mold machining are a guarantee of long-lasting molds. Frequent maintenance and repair of molds will increase the lifespan of multi-cavity injection molds and ensure an equal quality production.

Plastic Injection Mould: Future Production Workhorse

Mass production of plastic components of good quality cannot be achieved without plastic molds. Key features include:

- Capability to make dimensionally correct and detailed components.

- In as little as 1-2 weeks, the T1 sample production will begin.

- ISO 9001:2015, ISO 14001:2015, and IATF 16949:2016 certification compliance.

- None of the minimum order requirements, suitable for prototype and small-volume production.

Be it in a custom plastic mold solution or in a multi-cavity mold that is ready to be implemented in production, the molds allow manufacturers to produce high-quality parts all the time.

Use Cases

Multicavity Injection Mold Design: It is important to think about the balancing of the cavities, cooling of the mold, and the choice of materials when designing a production mold with high efficiency.

The Materials of Multi-Cavity Injection Moulds: Multi-cavity injection moulds have increased the speed of production, lowered production costs, and ensured replication of plastic components.

Automobile and Consumer Product Multi-Cavity Molds: Satisfy mass production multi-cavity plastic molds that are industrial-grade.

Custom Multi-Cavity Molds to Prototype: Perfectly suited to the quick development and testing of plastic components.

Industry Benefits

Auto: Multifaceted dashboards, casing, and engine components.

Medical: Medical devices and parts of high tolerance.

Consumer Electronics: Cases and complex plastics.

Consumer Goods: Toys, kitchenware, and packaging solutions.

Prototyping and Low-Volume Production: Rapid product development.

Sunon Mould is a manufacturer of high-quality multi-cavity molds.

Conclusion

It is an injection mould with multi-cavities, which is a pillar of modern plastic manufacturing, relying on accuracy, effectiveness, and flexibility. These molds can be used in cost-effective, repeatable, and quality production of plastic components, whether in high-volume industrial production or in the development of prototypes.

Having high-quality tooling, plastic part mold design service, and automation integration allows the firms to have high-quality plastic replication, ensure high-quality standards, and satisfy the rapid market environment. To have a chance to see our complete services and many others, visit SunOn Mould and have innovative and reliable custom multi-cavity injection molds.