Medical Device Overmolding | Custom Two-Shot Solutions

What is Medical Device Overmolding?

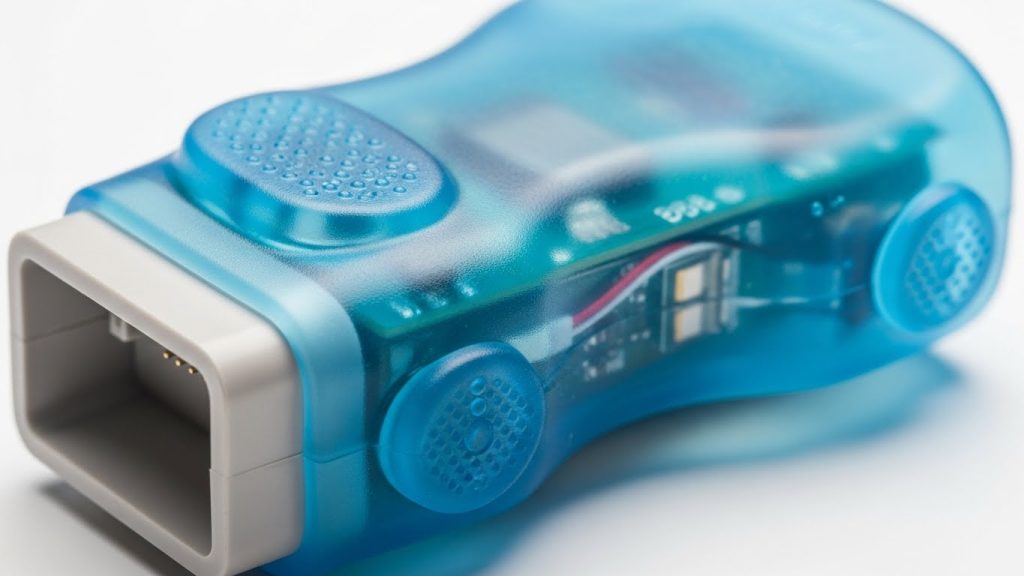

- Medical device overmolding is a complicated fabrication technique that involves the integration of two or more materials into one cohesive unit. This process is frequently done in two-shot molding of medical devices, bi-material injection molding of medical components, it can be used to create soft-touch finishes, ergonomic grips, two-color finishes, and high-function assemblies.

- Overmolding, as compared to the traditional molding process, not only removes the process of assembling, but it also lowers the manufacturing cost of labor and increases the performance, biocompatibility, and aesthetic of the medical equipment. The integration of such materials as thermoplastics, silicones, and TPEs allows the manufacturers to design the components that may be handled, withstand sterilization, and meet all healthcare requirements.

Why SunOn Should Be the Preferred Provider of Medical Overmolding?

SunOn has a reputation as a high-end OEM medical overmolding manufacturer that has had decades of experience in manufacturing medical devices of high precision. Our medical overmolding processes are designed to address the tough demands of the medical device manufacturers all around the world.

The main benefits of SunOn's choice are:

- High-Precision Molding: The use of high-tech multi-cavity molds.

- Material Knowledge: Knowledge of biocompatible overmolding, such as silicone-to-plastic overmolding.

- Automated Production Lines: Guarantees high-volume and quality production.

- Custom Solutions: Overmolding Can Be Turnkey: Our overmolding solutions are available in prototype medical overmolding, as well as in full-scale manufacturing.

- Regulatory Compliance: FDA-compliant processes that are appropriate to medical-grade components.

Through medical device injection molding, dual material injection molding medical components, and soft-touch overmolding of medical devices, SunOn provides components that perform very well in terms of performance, safety, and ergonomics.

Medical Device Overmolding Uses

The application of medical device overmolding is found in a broad range of medical practices, which offers durability, comfort, and functionality:

Surgical Instruments

- Surgical tools are two-shot overmolded to provide ergonomic handles, a non-slip surface, and biocompatible materials.

- Overmolding solutions (with multi-materials) enhance sterility and durability.

Diagnostic Equipment

- Overmolding of diagnostic equipment promotes more accuracy, comfort ability and usefulness.

- Bi-material over-molding medical components offer solutions that offer functionality and tactile response to delicate tools.

Healthcare Devices

- Overmolding with the soft-touch of medical equipment enhances the comfort of prolonged procedures for users.

Such components as thermoplastic overmolding medical parts and dual-material injection molding medical parts enhance durability and chemical resistance.

Medical Overmolding Techniques Advantages

The overmolding procedure of medical equipment provided by SunOn ensures high-quality performance and cost-efficiency and is performed by means of technical skills and the latest tooling:

- Seamless Material Bonding: Provides part strength, long-lasting, and bi-material bonding.

- Precision Molding: Advanced medical overmolding mold flow analysis ensures uniform quality.

- Multi-Cavity Production: This is a method that maximizes cycle times and enables the production of large volumes of medical overmolding.

- Automation of Production Lines: This saves labor expenses and enhances repeatability.

- Thermoplastic and Silicone Integration: Enables silicone and thermoplastic overmolding of medical products, respectively.

- High-Tolerance Overmolding: Enhances compliance with the FDA-conformable standards and ergonomics.

The medical two-shot technique offers SunOn the chance to create complex geometry molded products, such as over-molded ergonomic handles on medical instruments, diagnostic equipment enclosures, and soft-touch healthcare products.

Overmolding Media in Medical Devices

The choice of the material used is very important to medical applications because it influences biocompatibility, durability, and sterilization. SunOn deals with a large variety of medical-grade materials:

- Thermoplastics: ABS, PC, PP, and PE of structural parts.

- Silicone and TPE: To soften hand ergonomics.

- Bio-Compatible Polymers: Adherent to FDA and ISO standards.

The compatibility of resin, control of the temperature of the mold, and the dynamics of polymer flow should be optimized to ensure that the process of medical molding is exact with a perfect finish and a high quality of performance.

Experience in Making Medical Overmolds at SunOn

SunOn offers custom medical overmolding solutions that respond to various healthcare and medical device needs. Our offerings include:

- Prototyping: Concept to first production.

- Contract Manufacturing: Overmolding of large volume medical, OEM clients.

- Turnkey Solutions: 100 percent overmolding of ergonomic medical handles, diagnostic equipment, and surgical instruments.

- Higher Tooling Design: Multi-cavity moulds, overmoulding tools of medical parts, automated overmoulding production lines.

With a combination of fabrication of medical components, FDA-compliant overmolding, and precision molding of high-tolerance components, SunOn provides solutions that are both regulatory and functional.

Benefits of Cooperation with SunOn

The engagement with SunOn to overmold medical devices will be a strategic advantage to manufacturers:

- Increased Ergonomics: Overmolding and use of dual-material injection molding medical parts to enhance their usability.

- Better Aesthetics: Two-shot and multi-material molding create high-quality and appealing components with appeal.

- Lower Cost of Production: Fewer assemblies and optimized overmolding of medical plastics.

- High-Volume Efficiency: Automated lines and multi-cavity medical overmolding molds are scalable.

- Governance Compliance: Materials and processes are of medical quality.

Having decades of experience, SunOn guarantees every medical overmolding project to be as reliable, innovative, and long-term valuable.

Medical Overmolding Trends of the Future Will Include:

- A combination of soft and hard surfaces in medical instruments and wearable devices.

- Production lines that are more accurate and automated.

- OEM and private-label healthcare products are customizable.

- Improved biocompatibility and sterilization-resistant materials.

SunOn remains innovative through its precision medical device molding, silicone overmolding medical applications, and custom medical overmolding partner solutions, thus remaining the choice of medical manufacturers all over the world.

Conclusion

SunOn is the best medical device overmolding company when it comes to medical device manufacturers who are interested in precision, reliability, and innovation. Incorporating technical know-how, innovative tools, and automated manufacturing of parts, SunOn develops two-shot components that have been perfected in functionality, comfort, and beauty to meet the requirements of the medical equipment sector, including healthcare device solutions consisting of multiple materials. Collaborate with SunOn to get high-quality, scalable, and novel medical device over-molding services.