Lighting Silicone Compression Molding | Custom Components

What is Lighting Silicone Compression Molding?

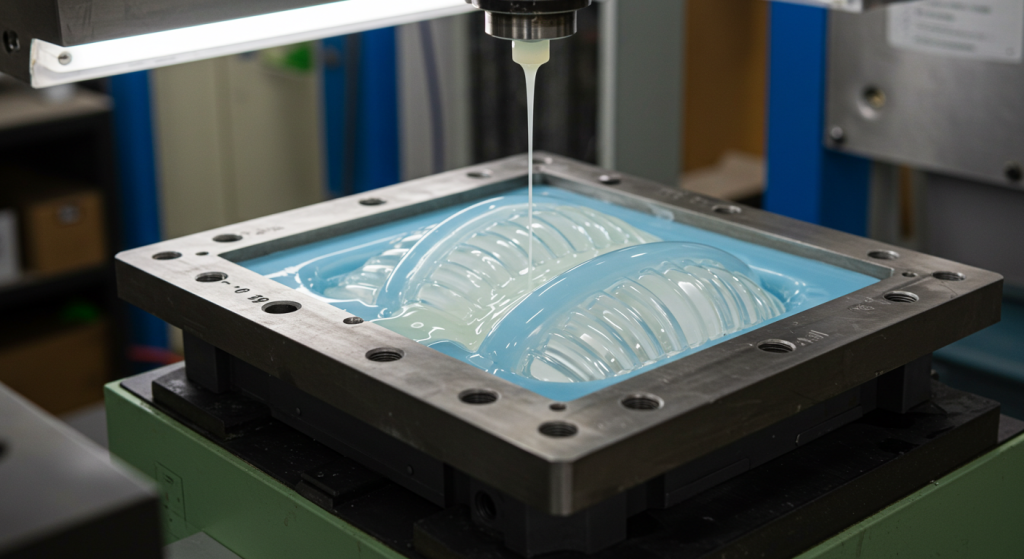

The process of molding is the molding of thermoset silicone with lighting integration. During this process, silicone polymer is put in a heated cavity mold. The lighting silicone compression molding is then cured under the applied heat and pressure, forming precise castings of silicone parts.

Advantages of SunOn Lighting Silicone Molding

1. High-Quality and Consistent Products

The process has constant silicone part tolerances, most of them being within ±0.2mm and ±0.5mm, depending on the part’s complexity. The parts produced from lighting silicone molding serve smooth and flawless optical and dimensional properties, which the LED lenses and diffusers require.

2. Versatility Across Lighting Applications

The components produced with lighting silicone compression molding include:

- LED and Smart light devices

- Architectural and Decorative Lighting

- Industrial Lighting Fixtures

3. Material Selections for Desired Functionality

Multiple silicone grades may be utilized accordingly:

• High-temperature silicone that can be used for heat-resistant lighting parts.

• Industrial silicone grade that can produce silicone parts for strong and long-lasting uses.

• Consistently stable molding and molding with thermosetting silicone for increased and better mold temperature.

4. Silicone Lighting Cost Saving Tooling

In comparison with other molding methods, compression molding for lighting silicone has the lowest tooling expenses. High volume production permits the use of multi-cavity molds, and thus serves as a productive molding technique for silicone lighting to lessen the isolation price.

5. Alterable Production

The production can support an almost unlimited variety of complex forms and diameters. From small gaskets and seals to huge silicone lenses and diffusers. This is very beneficial for silicone parts used for LED illumination that possess complex molds or are used with multi-cavity molds.

The Silicone Molding for Lighting Process

The rubber molding for lighting applications has a clear, trustworthy sequence of operation.

1. Preparation of Materials

Silicone Sheets or pellets of the needed grade for the desired parts' illumination silicone molds.

2. Tooling and Design of the Molds

Lighting device silicone molding is done with the use of single and multi-cavity molds that permit the precision molding of silicone for lighting devices.

3. Preheating the Mould

The mold is kept at a set temperature of 50 degrees Celsius to thermoset properly when processing elastomers for the lighting parts. This results in a steady silicone flow as well as even curing.

4. Placing the Silicone Moulding Compound

The silicone is pre-weighed to ensure that the silicone filling in the mold cavity covers even the most intricate features.

5. Heating the Silicone Moulding Compound

The closed mold is kept at specified temperature and pressure conditions until the silicone parts have cured. The result is silicone components for lighting, which are durable and flexible as well as heat-resistant.

6. Demoulding

Both the trimming and polishing processes are optional and are done to meet the standards set for silicone components used in lighting, which are kept at a very high value.

The bulk of the business policies is oriented on the fundamental requirement of maintaining the constant quality of the business:

- Tolerance: parts are ±0.2mm to ±0.5mm according to the complexity of the part.

- Cavity Molds: allow for the production of a high volume of molds.

- Categorized Silicone: used can be high-temperature silicone, industrial-grade silicone, or thermoset silicone.

- Cost of Tools: still cheaper in comparison to injection molds.

- Dimensions: can range from very small gaskets to large diffusers for LEDs.

- Certain Sectors: these include LED lights, smart lighting, decorative lighting, and even industrial lighting.

Applications of Lighting Silicone Compression Molding

1. LED Lighting Components

The custom parts for LED lighting comprise lenses, diffusers, gaskets, and seals. Lighting silicone compression molding for LED devices guarantees dimensional accuracy, optical clarity, and robustness.

2. Smart Lighting Devices

The silicone compression molding for smart lighting devices yields silicone parts that are flexible, heat-resistant, and protect delicate electronics, all while upholding design beauty.

3. Decorative and Architectural Lighting

For the artistic or architectural enhancements of the silicone rubber molding for decorative lighting, custom shapes and finishes are combined. These include LED silicone diffusers and silicone gaskets.

4. Industrial Lighting Applications

The silicone compression molding for industrial lighting creates silicone components that can endure high temperatures, UV radiation, and rugged conditions, making them suited for outdoor and factory lighting systems.

Custom Lighting Silicone Fabrication Solutions

At SunOn, we offer complete services for lighting silicone molding. These include:

• New low-volume prototypes for lighting design

• Industrial multi-cavity high-volume production

• Smart lighting and LED silicone precision molded parts

• Components that are flexible and heat-resistant

• Lighting silicone custom fabrication

We ensure all parts are compliant with your design specifications, industry standards, and durability requirements.

Advanced Techniques Include

- Lighting silicone molding with tight tolerances

- Stability and performance of thermoset silicone molding for lighting applications

- Flow and curing silicone lighting component compression mold design

- High production multi-cavity silicone molds

These approaches ensure efficiency with production and quality silicone molded parts for lighting devices.

Benefits of Silicone Compression Molding

Durability:

Silicone parts for LED and smart lighting production remain long-lasting

Precision:

Tight tolerances for optical and mechanical performance were achieved

Cost:

Tooling and production expenses reduced

Flexibility:

Multi-cavity molds and complex shapes, along with custom components, are supported

Application:

LED, smart, decorative, and industrial lighting

Conclusion:

The conclusion is that lighting silicone compression molding is effective and time-saving for making silicone parts for industrial, smart, decorative, and LED lights. It is also precise and produces quality silicone components. Durable and flexible silicone parts that fulfill stringent requirements are guaranteed with the molding of LED lenses, diffusers, silicone gaskets, and seals. SunOn offers precise and efficient molded silicone parts for industrial-scale production and low-volume prototyping in custom lighting silicone molding. Our proficient team handles everything for you and guarantees superior quality and efficient molding for all your lighting needs.