High-Precision Alu-Zinc Die Casting Tooling | Custom Molds

What is it?

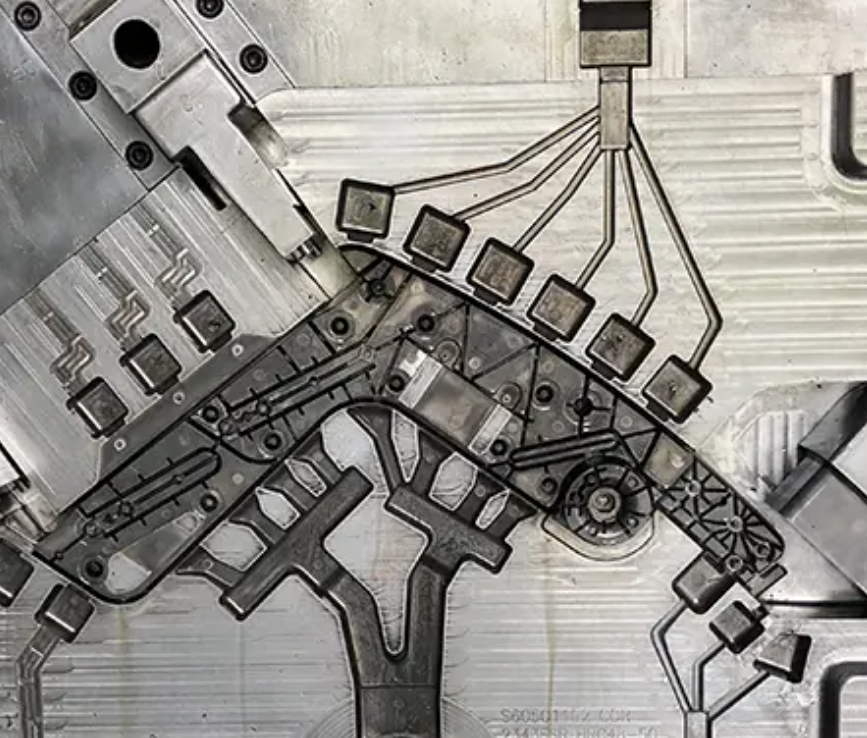

High-precision alu-zinc die casting tooling is a special-purpose design mold that is utilized in the die casting of aluminum and zinc. These are designed to create complex geometry die molds that have tight tolerances so that repeated die casting can be done with minimal wastage.

Unlike conventional methods of casting, precision die casting tooling is used to guarantee:

- Stability of die molds during dimension.

- Constant quality of components.

- Large-scale efficiency in industrial production.

- Prolonged molds that can be used indefinitely.

This renders industrial die casting tooling the best in the automotive, electronics, and consumer goods industries, where quality and precision are the main concerns.

Materials and Construction

Alu-zinc alloy die casting requires high-strength tool steel or other metals of strength to resist high injection pressure and number of repetitions. The important factors in the die mould making are:

- Rapid cooling and solidification of die molds thermally.

- Metal casting with high accuracy in the details.

- Die-cast tool steel that is wear-resistant.

- CNC die casting tooling for high precision machining.

- Multi-cavity die casting molds are supported by mass production.

This powerful tooling guarantees high cycle times of die casting, and the same quality of thousands of parts can be produced.

From Design to Production

The process of a high-precision aluminum-zinc die casting tooling starts with an accurate design and prototyping of the mold.

Evaluation and Negotiation of Price

The first step taken by the manufacturers is to take part in drawing customers, clarify project needs, and negotiate costs to achieve cost-effective solutions of high-volume die casting at low costs.

Design Analysis

Engineers are able to detect the possible design difficulties, casting tolerance control, and manufacturability optimization ahead of the manufacturing process.

Mold Design

The mold is precisely engineered with parting faces, injection apparatus, and cavity arrangements that are part-specific. Design has also been important in maintaining dimensional consistency of die molds and easy working in mass production.

Mold Making

Manufacturers make all the mold components with accurate precision using modern technologies such as CNC machining, milling, turning, and EDM. Assemblies are then made and tested of molds of multi-cavity die casting molds or complex geometry die molds.

The Die Casting Process

The production process involves alu-zinc die-cast molds. The steps include:

- High-pressure injection of molten alloy into high-precision molds.

- Quick cooling to maintain the correct size and eliminate defects.

- Cast component ejection to post-processing.

- Surface finishing, deburring, and high-quality trimming.

It ensures that there is repeatable die casting production and that it is also possible to produce durable, high-precision die casting dies that can be used in the automotive, electronic, and industrial industries.

Uses in the Industry

Automotive

Automotive die casting tooling gives manufacturers the opportunity to create complex pieces using advanced die casting tooling. The multi-cavity designs help to shorten the production time without compromising the level of tolerance.

Consumer Electronics

The dying of aluminum-zinc housings, connectors, and other precision parts needs to be capable of fine detail and repeatable on a thousand-unit scale.

Industrial Equipment

The alu-zinc die casting molds used by heavy machinery and industrial devices are also of industrial grade; therefore, high-volume production of metal components is produced with minimal defects and less waste.

Consumer Products

Custom alu-zinc die cast molds are available in electronics casing, home appliance manufacturing, and complex geometry die molds, are of the flexibility to produce parts that are both aesthetically and functionally appropriate.

Benefits of High-Precision Alu-Zinc Die Casting Tooling

Complex Geometry Capability

Die cast, CNC, and automated die casting moulds give manufacturers the ability to make components with complex designs and high tolerances.

High-Volume Production

The multi-cavity die casting molds can produce several parts simultaneously, which will shorten the cycle times significantly and make them more efficient.

Dimensional Accuracy

Developed aluminum-zinc tooling design provides dimensional stability of die molds, which is important in such industries as automotive and electronics.

Durability and Wear Resistance

Made of tool steel to die cast, high precision molds are reusable, and have a consistent quality during a long production cycle.

Cost Efficiency

This is because initially the tooling cost might be expensive, but in the long term, the material, labour, and production time saved will be recovered to make high-precision die casting tooling cost-efficient in mass production.

Technical Insights

Thermal Management

Die casting possesses adequate thermal control to provide fast cooling of the casting, eliminating warping as well as defects, and is highly efficient in production molds.

Automation Integration

Recent CNC die casting moulds are easily compatible with automated die casting systems, enhancing output capacity and decreasing human error.

Quality Control

Tolerance control and high-accuracy metal tooling also ensure that every component is produced to high specifications and that the quality of components remains the same.

Maintenance

Scheduled maintenance and repair of the molds extends the life of industrial die cast tooling and ensures consistency in production in the long run.

What is the Benefit of Using Alu and Zinc Alloy Die-Casting Molds?

Alu and Zinc Alloy Die-casting Mold solutions are the best solutions that a manufacturer should consider in order to have high-quality aluminum and zinc components. Key benefits include:

- Detailed information and correct proportions.

- Wear and tear resistance during continuous production.

- Help in the adequate cooling and solidification of alloys.

- Specialized in the design of components.

In the long run, it lowers the cost of production when dealing with large-volume production.

These molds can be custom cast aluminum-zinc die cast molds to be used by the industry, and also durable, high-precision die cast die that may be utilized in repeated production.

Conclusion

Production of metal components is revolutionized through high-precision alu-zinc die casting tooling, which integrates accuracy, efficiency, and durability. Multi-cavity die casting moulds that are used in mass production of components through the creation of many moulds are some of the solutions that enable manufacturers to produce high-quality components, repeatable production, and lower manufacturing costs.

To get custom services of high precision die casting, consider SunOn Mould as an innovative service in the industrial-grade aluminum-zinc die casting molds.