Fast Turnaround Injection Mould | T1 Sample 1-2 Weeks

What is Fast Turnaround Injection Moulding?

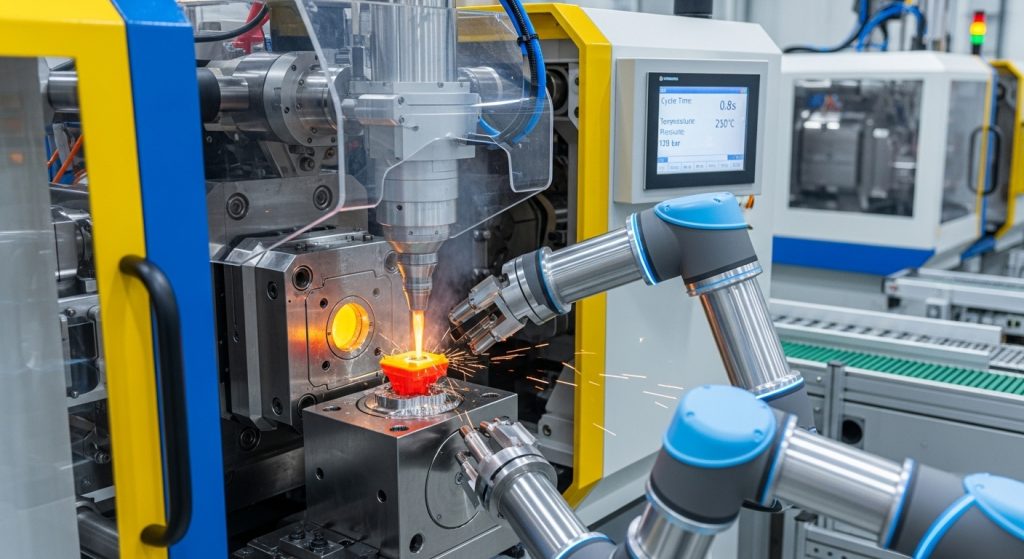

Fast turnaround injection moulding is a highly efficient, fast process of creating moulds and prototypes within an unusually short amount of time. The conventional injection moulding schedules can take weeks or months to be completed, but with rapid tooling and streamlined design processes, manufacturers can now attain rapid prototype moulding, express mould production, and rapid mould fabrication in days.

The benefits of such a solution are evident, being speedy product development, reduced development cycles, and cost-efficient production, particularly when dealing with low-volume injection moulding or custom plastic parts.

The major Highlights of Fast Turnaround Injection Moulds:

- Instantaneous tooling injection moulds of prototypes and production.

- The rapid production of moulds with high precision.

- Injection moulding of T1 samples (short lead-time injection moulding 1-2 weeks).

- Long-life materials for moulds.

- Efficient production through optimised mould cycle times.

Why Oppose Fast Turnaround Injection Moulding?

Companies cannot afford to lag in developing products. The old paradigm of concept and production may halt innovation and delay the time-to-market. Fast turnaround injection mould solves these issues by offering:

Speed without Compromise

T1 samples can be made in only 1-2 weeks with fast injection moulding and throughput in order to have designs tested, test materials used, and make iterative improvements easily.

Cost Efficiency

The short lead times will minimise labour and overhead costs. Combined with low-volume injection moulding and short-run injection mould production, businesses get to attain solutions that are cost-effective but do not compromise quality.

Prototyping and Production Flexibility

Quick tooling enables you to experiment on prototype injection moulds, custom injection moulds, where the mould is delivered fast and mould fabrication, which delivers products best suited to market demands in a short time.

High-Quality Output

Precision is not lost even on hastened production schedules. The completed parts are machined or fabricated using CNC-machined moulds, steel moulds, and aluminium mould tools to high tolerances (+-0.1mm) and a high quality of surface finish; glossy, matte, textured or UV-coated.

Technical Benefits of Rapid Injection Moulding

Existing fast turnaround injection mould is based on technical improvements which improve the performance, durability and efficiency:

Mould Cavity Optimisation: Ensures of constant flow of material and minimisation of defects.

High-Precision Moulding: Multi-cavity moulds can support high-volume and still maintain quality.

Thermal Control Systems: Control the temperature and minimise warping and shrinkage.

Durable Mould Materials: Steel and aluminium moulds are durable and repeatable.

Mould Flow Simulation: Simulates part action during injection, fill patterns and cycle time optimisation.

These technologies make sure that fast mould tooling solutions do not just provide speed, but they give precision, uniformity and dependability.

Uses of Fast Turnaround Injection Moulds

Applications: Fast turnaround injection moulding has a wide variety of applications across a range of industries:

Automotive Components

Manufacture quickly, high-quality engine components, dashboard components, and plastic housings, where the design of custom moulds allows compatibility with complex geometries.

Consumer Electronics

From phone cases to small electronic boxes, rapid tooling can be used to achieve quick prototyping, testing, iterative designs and mass production.

Medical Devices

The rapid turnaround of the lead times is important in the creation of prototype medical devices and components, where accuracy, choice of materials, and standards are of utmost importance.

Industrial Plastic Parts

High-speed injection mould production and accurate injection mould tooling can be used in custom industrial components, including enclosures, brackets, and mechanical assemblies.

Small Batch and Short-Run Production

In the cases of startups or low-volume production, short-run injection mould production and on-demand moulding will offer low-cost options without long-term tooling contracts.

Materials and Mould Options

The key to fast turnaround production is Plastic Injection moulding. It is compatible with thermoplastics, which include ABS, PC, Nylon, PP and others. In combination with overmolding and insert moulding, manufacturers are able to produce multi-material components with complex geometry and skinny walls and still with tight tolerances.

Mould Options Include:

- Mass production of high-cavity/ multi-cavity moulds.

- Prototyping/low-volume Custom mould design and rapid tooling.

- Surface finish: Glossy, matte, textured, UV finish, plating and so on.

- Lead times 7-30 days based on volume (1k-1M+ pcs).

These options will allow the use of your rapid tooling services to support a broad range of production requirements, including prototype injection moulds to high-cycle mould production.

The Fast Turnaround Injection Mould Process

A lean and agile system is needed to deliver T1 samples within 1-2 weeks:

Design Optimization

The engineers are involved in the optimisation of mould cavity design, multi-cavity layout, as well as tooling accuracy to achieve rapid and precise production.

Rapid Tooling Fabrication

Moulds and high-speed methods of producing moulds are produced with the use of CNC machining, thus tooling can be produced in a short time, without compromising quality.

Prototype Testing

The T1 samples are first subjected to rigorous surface finish/dimensional accuracy and/or material performance.

Full Production Run

The mould is deployed to short-run or high-volume production once it has been approved, and the consistency of quality and shorter injection mould cycle time is achieved.

Final Inspection & Packaging

All the parts are checked in terms of tolerances, cosmetic finishes, and functionality before delivery.

Why Sunon Mould Will Be Your Perfect Partner?

Our Sunon Mould Company specialises in quick turnaround injection moulding, which provides T1 samples within 1-2 weeks to the industries in need of velocity, accuracy, and dependability. Our services include:

- Injection moulds of tools in a hurry.

- Custom injection mould that is fast delivered.

- Fast-moving plastic parts manufacturing.

- Injection mould production in the short run.

- Prototype injection moulds

We mix our high-level CNC-machined moulds, steel and aluminium fabrication and thermal control systems to provide durability of the mould materials and accurate injection mould tooling.

Incorporating high-speed prototyping, agile production, and high-speed mould design, Sunon Mould can turn your ideas into solutions ready to be used in production at a faster rate than would be possible with other methods.

Advantages of Fast Turnaround Injection Moulding Services

Quick Product Development

Rapidly transfer ideas to prototype using express mould manufacturing and faster mould creation, cutting time-to-market by a factor of many.

Cost Savings

Precision injection moulding with low-volume and low-cost fast injection mould tooling reduces the use of resources and maximises production efficiency.

High-Quality Output

Precision injection mould tooling and optimisation of mould cavity allows components to be tight and injection mould surfaces to be superior.

Flexibility & Scalability

We have short-run, mid-volume, and high-volume production with prototype injection moulds through to mass production tooling.

Industry Compliance

Our procedures comply with the industrial plastic parts standards, with the components being safe, reliable and fit to be marketed.

Conclusion

The process of product development and production is being transformed by the fast turnaround injection moulding. By having T1 samples in 1-2 weeks, the companies will be able to gain faster innovation, lower costs, as well as keep quality standards high. In SunOn Mould, we offer fast injection moulding, fast mould production, fast express plastic mould services and total plastic injection moulding services as per your needs.

Get the benefits of a fast tooling technology, get your mould lead time lower and enjoy the fruits of a quick tooling service on your next project. Our Mould will accelerate your product development process today, and you reliable supplier of fast turnaround injection moulds.