Electronics Overmolding Service | Custom Solutions

What is Electronics Overmolding?

Electronics overmolding is a type of specialized injection molding where thermoplastic materials such as TPU, silicone, or other elastomers are molded over electrical components or substrates such as plastic housings, metal frames, or circuit boards. The result of this process is integrated and multi-material components that are more durable, ergonomic, and aesthetic.

It allows the elimination of secondary assembly operations, lowers labor expenses, and offers single-source electronics molding options that incorporate TPU overmolding or silicone overmolding with rigid substrates, unlike traditional assembly methods.

The major advantages of Overmolding are:

- Improved grip, ergonomics, and touch.

- Better break-resistant and impact-resistant.

- Mazing together of various materials.

- Fewer assembly processes and labor expenses.

- Consumer-facing products with high-quality finishes.

With years of experience, SunOn Mould provides tailor-made electronics overmolding products to its clients at the most optimal quality to provide reliability to OEMs worldwide.

Electronics Overmolding: Innovative Solutions for High-Performance Components

The need to have electronics that are overmolded has increased in the current world, which has brought great technology since industries need electronics that are durable, ergonomically correct, and those that are more aesthetically appealing in consumer electronics, medical machines, automobiles, and other industrial machinery.

- Custom electronics overmold involves high precision and multi-material solutions. SunOn Mould is a leading company globally in offering electronics overmolding services that are designed to suit both prototyping with low volume as well as high volume production.

- Be it electronics overmolding of housings, soft-touch grips, manufacturing to cater to the needs of industries, SunOn's experience in mold fabrication, perfect bonding, and high-quality finishes that comply with the ISO standard all over the globe makes it the ideal choice.

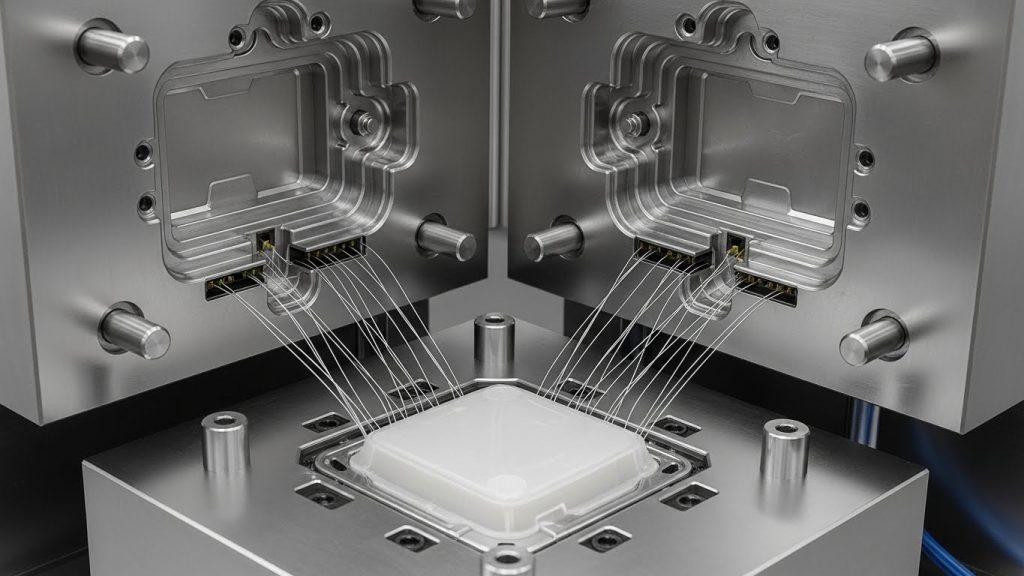

The Overmolding Process in Electronics

Electronics over-moulding process requires careful engineering, high-quality materials, and computerized systems to produce high-performance components:

- Electronics Overmolding Mold Cavity Design

The design of meticulous electronics housings' mold cavity is the main basis of all successful electronics overmolded components. Engineers take into consideration optimization of the placement of the gates, parting lines, shrinkage compensation, and tolerance management to have a perfect output. It Mold flow analysis forecasts the flow and bonding characteristics of materials and the cooling behavior of resins, minimizing defects and decreasing the indirect cost of material management.

- Placement and Preparation of Materials

Robotic overmolding systems take the electronic components, connectors, or metal inserts and precisely place them. Silicone or thermoplastic elastomers are made with desired hardness, flexibility, and bonding properties such that they adhere firmly to the substrate.

- Injection and Overmolding

Overmolding to the component is injected with molten TPU, silicone, or other overmolding materials to create a strong bond with the underlying materials. The step involves injection pressure optimization and thermoplastic overmolding of electronics methods so as to maximize the strength of the bonding material and the life of the part.

- Multi-Shot and Multi-Material Overmolding

Multi-shot overmolding can be supported on complex designs with multi-color elements needed, soft-touch surfaces, or integrated structural components by SunOn. In this method, overmolding and insert molding are possible, and the post-assembly process is not required.

- Cooling, Ejection, and Quality Inspection

Components are then molded, cooled, ejected, and checked on surface finish excellence, dimensional precision, and structural integrity. This guarantees that all the components are of a precision overmolding manufacturer.

Uses of Electronics Overmolding

- Consumer Electronics

Consumer devices overmolding produces soft-touch product housings, grips on mobile devices, and protective casings. With TPU overmolding or silicone overmolding, SunOn creates ergonomic designed components that avoid wear and tear, thereby enhancing the user experience.

- Automotive Electronics

Automotive electronics overmolding solutions have a benefit on components such as dashboard controls, connectors, and switches because they are impact-resistant, durable, and have soft-touch finishes. The manufacturing process of industrial electronics in SunOn introduces high-precision parts that are able to resist adverse operating environment conditions.

- Medical Devices

It is of medical devices are used in medical housings, surgical tool grips, and protective casings, and ensure cleanroom production, extremely high precision tolerances, and biocompatible materials to keep patients safe.

- Wearable Devices

Wearables need ergonomic electronics grips and flexible housings. Wearable devices that are overmolded with electronics guarantee comfort, durability, and beauty.

- Industrial Equipment

Industrial overmolding improves the protective enclosures, control panel, and industrial sensors to provide impact-resistant, durable, and accurately molded parts.

Substances in Electronics Overmolding

The performance and durability depend greatly on the choice of materials:

- TPU Overmolding: Flexible, impact-resistant, soft touch.

- Electronics Silicone Overmolding: Durability, high temperature resistance.

- Thermoplastic Elastomers: Multi-material bonding and soft-touch solutions.

- Heat-Stable Overmolding Materials: Withstand structural stress.

- Polymer Overmolding Reinforced: A high mechanical strength.

SunOn provides the best plastic-to-plastic electronics bonding, plastic-to-metal overmolding to achieve long-term and high-performance outcomes.

Plastic Injection Molding Expertise, SunOn

SunOn can create plastic injection molds to enhance the electronics overmolding production, with accuracy in the production of housings, enclosures, and complicated parts. Combinations of electronics injection molding and overmolding allow continuous multi-material components with high levels of structural integrity.

The most important benefits of SunOn Injection Molding are:

- Electronic components molding with high precision.

- Multi-material multi-shot molding.

- Low and high volume run production is cost-effective.

- High-quality surface finishes and ergonomics.

High-Tech Tooling and Machinery

SunOn uses the most recent technologies in overmolding:

- Accurate electronics overmoulding tooling.

- Electronics Robotic insert loading.

- Molds are machined with a CNC machine and are durable.

- Automated overmolding machines.

- Multi-shot and multi-material molding machines.

Such abilities guarantee the uniform quality, optimal cycle time, and efficiency in high-volume production.

Conclusion

Ergonomic design, material innovation, and precision engineering are converging in electronics overmolding that is changing component manufacturing. Soft-touch consumer electronics to durable car and medical components, overmolding will guarantee an active, attractive, and durable component. SunOn Mould is a leading company in the field of custom overmolding that provides accuracy in terms of mold fabrication, multi-material integration, and high-performance injection molding solutions.