Custom Silicone Mold Casting Plastic | High-Precision Molds

Custom Silicone Mold Casting Plastic: Precision, Flexibility, and Industrial Excellence

Custom silicone mold casting plastic has become a crucial technology in the contemporary manufacturing industry, and it has transformed the manufacturing process of high-precision plastic parts. Since silicone molding of plastic is used to cast plastic, and silicone rubber molds are used to cast plastic in industrial applications, silicone molding offers flexibility and reliability in both small-scale prototyping and large-scale production.

Silicone molds have also grown to be a popular solution to industries where complex, robust, and accurate components are needed, such as medical devices, automotive parts, consumer electronics, and hobbyist projects. With the combination of sophisticated silicone mold fabrication technology, the manufacturers can come up with exquisite designs that were previously challenging or unattainable using traditional mold-making technology.

What is the Rationale Behind Custom Silicone Mold Casting Plastic?

High Precision and Accuracy

Plastic High-precision molds in silicone enable the manufacturer to create parts with very high precision, commonly between +-0.2mm to +-0.5mm due to the complexity of the part. The precision is used to guarantee uniform plastic prototype casting, which is vital in functional testing and commercial manufacturing.

Design Flexibility

Custom silicone molds of plastic afford the latitude to develop complicated forms of geometry without compromising durability, regardless of the size of the seal or a big industrial part. Silicone molds: Two-part silicone molds and liquid silicone molds of plastic allow sophisticated designs that can accommodate undercuts, fine textures, and delicate details.

Cost-Effective Production

Silicone mold making of plastic parts is cheaper in terms of initial tooling compared to traditional injection molding. This is particularly useful in the small-volume production of plastic molds or in manufacturing projects that require low-volume production but high quality, where cost-effectiveness is just as significant as accuracy.

Reusability and Durability

Plastic casting, Reusable silicone molds are intended to be reused many times without much wear. Plastic silicone rubber molds provide high quality and accuracy in dimensional stability and finish of smooth surfaces, and thus offer consistency of the parts during manufacturing cycles.

Silicone Compression Molding: A Multi-Purpose Process

Compression molding of silicone is among the most commonly used manufacturing processes in custom silicone mold casting plastic. The method enables the synthesis of high-quality silicone parts with stable and reproducible outcomes. Key advantages include:

- Silicone complex parts production.

- The large volume production by means of molds with multiple cavities.

- +-0.2mm to +-0.5mm tolerance control

- In comparison to other molding processes, relatively low tooling cost.

- The capability to be used with different silicone grades, such as medical and industrial silicone.

Silicone compression molding is highly beneficial to industries such as medical, automotive, and consumer goods because the products can be designed to fit tightly without compromising their quality, besides having flexibility and scalability.

To learn more about our silicone molding products, go to our services page.

Custom Silicone Mold Casting Plastic is Used in Applications

Prototype Development

Three-dimensional Prototyping Plastic prototype casting with own silicone molds of plastic enables designers to test shape, fit, and perform before mass production. Simple silicone molds can be created through rapid prototyping as a cost-effective method of prototype testing.

Industrial Production

Plastic silicone molds are best used in manufacturing small batches and medium-sized parts. The silicone material is flexible, leading to production-ready molds capable of accommodating complex geometries and undercuts, which are used to guarantee uniform production quality.

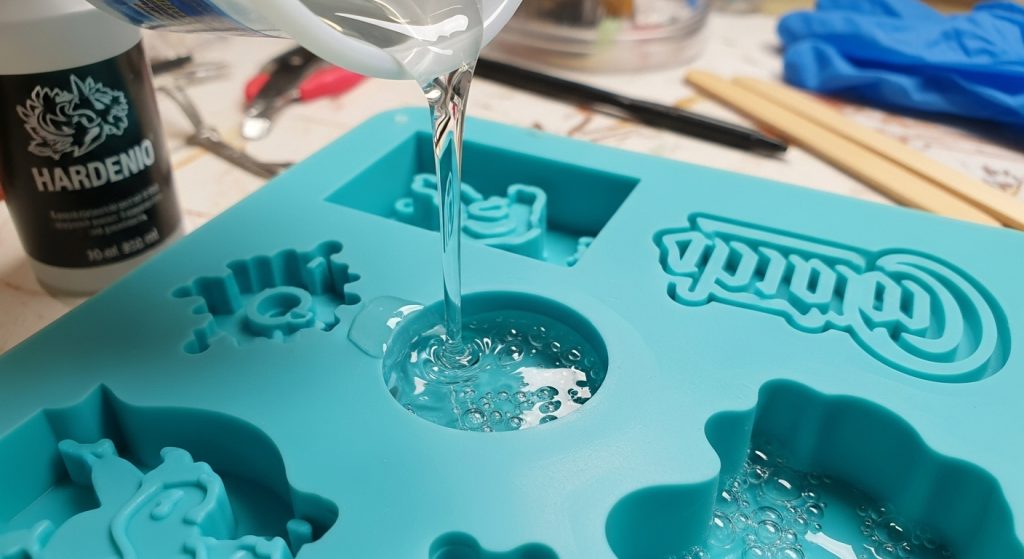

DIY and Hobbyist Projects

In the case of hobbyists and small-scale designers, DIY silicone mold casting plastic will create the possibility of producing a complex product, such as a custom figurine, a decorative item, and a resin-based plastic piece.

Specialized Industries

The medical, electronics, and automotive industries are the types of fields where engineering-grade plastic castings are needed, and both accuracy and reliability cannot be compromised. Precision Silicone molds are used in plastic production to meet such requirements, producing parts with smooth surfaces, dimensional stability, and high repeatability.

Silicone Mold Technical Benefits

High-Detail Mold Accuracy

Silicone rubber molds are utilized to capture all the design details, such as textures, logos, and finer details. This is necessary in prototype functional molding and decorative parts.

Silicone Molds are Resistant to Heat

There are also some silicone casts of plastic that can withstand high temperatures and are therefore useful in thermoset plastic casting and other heat-sensitive procedures.

Flexible Molding Material

Silicone has a high elasticity and thus, even undercutting shapes can be easily demolded without the destruction of the part or the mold.

Vacuum Casting Facilities

Vacuum casting is used together with silicone molds to eliminate all the air bubbles and produce smooth and high-quality plastic parts.

Silicone Mold Design and Fabrication

An effective mold will guarantee high productivity and economical production. The services provided by our silicone mold designing are:

Design a Custom Mold: Specific to part geometry.

Precision mold tooling: CNC-aided tooling of complex designs.

Mold Creation: 3D modeling, prototyping Rapid prototyping.

Detailed Mold Patterns: This is used to make complex features replicated accurately.

Quick Prototype Molds: Small lead times in product development.

With the incorporation of high-tech silicone molds, the manufacturers are capable of coming up with durable, reusable silicone molds that can be used in repetitive casting procedures to ensure uniformity in the quality of parts.

The Silicone Mold Casting Advantages

Durable Silicone Molds: This type of Mold is designed to be reused many times.

Reusable Molds to Casting: Economical and green.

High Variety of Forms and Sizes: Small seals up to giant industrial parts.

Scalable Production: Can easily be adjusted between small-scale prototyping and large-scale production.

Smooth Finish: Less work after it is done, plus the result is a professional finish.

Conclusion

Custom silicone mold casting plastic is not simply a form of manufacturing; it is a kind of transition between the flexibility of design and the precision of industry. Silicone mold technology provides a robust and precise, as well as a beautiful outcome, whether in high-volume production, batches of low-volume prototyping, or in custom components with high precision.

Since silicone compression molding is used in the production of medical and automotive products, as well as in the creation of DIY projects in mold casting plastics, silicone molds are a very versatile and efficient tool in the contemporary manufacturing industry. SunOn Mould can be found in innovative and high-quality solutions in custom silicone molds that are used in plastic production.