Custom Overmold Tooling Solutions | Multi-Material Molds

High-Precision Solutions to Modern-Day Manufacturing

The modern manufacturing sector is characterized by a high pace, and precision, efficiency, and versatility are the keystones of the provision of high-quality parts. Custom overmold tooling has become one of the pillars of technology in the industry that needs parts that are multi-material and with high precision to be molded. In the automotive interiors sector, consumer products, electronics, and medical equipment, overmold tooling can provide products of high quality and maximize the efficiency of production.

At SunOn Mould, we focus on providing state-of-the-art overmolding tooling solutions that are based on both innovative technology and manufacturing experience. A unique production requirement means that our custom injection overmolding tooling services and multi-material overmolding tooling services are designed to fit your specific requirements, making them durable, more accurate, and providing high performance.

What Does Custom Overmold Tooling Mean?

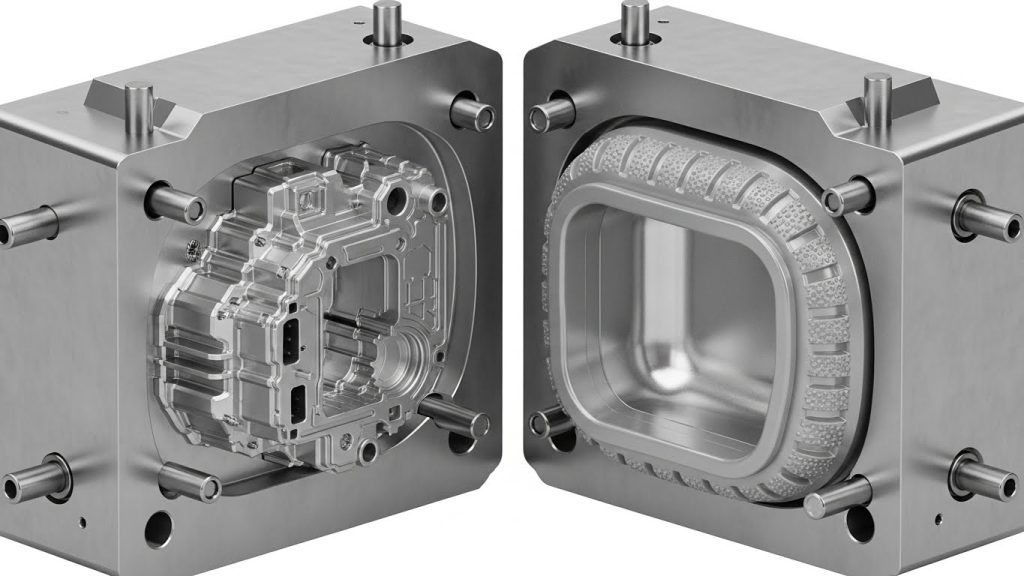

The process of creating and producing mold types that enable two or more materials, usually plastic and rubber, to be molded together smoothly is called custom overmold tooling. Also known as two-shot or multi-shot overmolding, this operation is necessary in the creation of ergonomic handles, soft-touch consumer parts, automotive parts, and electronic housings.

The overmold tooling is tailored to specific part geometries, material combinations, and volumes of production, unlike ordinary molds. Through overmould design and high-precision overmould tooling, manufacturers can attain a high level of dimensional accuracy, high material adhesion, and high surface finishing.

The Major Benefits of Custom Overmold Tooling

High-quality overmold tooling has many advantages:

Great Accuracy and Uniformity

SunOn produces molds with consistent dimensions across thousands of production cycles through cutting-edge CNC mold production in the form of overmolding, EDM tooling production, and tooling tolerance management. This guarantees the production of all parts that are of design specifications with few defects.

Multi-Material Capabilities

A combination of soft-touch elastomers, TPEs, and rigid plastics in a single part is possible using our multi-material overmolding tooling. This feature is critical in ergonomic handles, consumer electronics, and medical equipment that need comfort and durability.

Efficient Production Optimization

Optimization used in overmold tooling is to reduce delays in manufacturing, optimize cooling channels, and also optimization of the cycle time, which makes the manufacturing more efficient.

Strong Material Bonding

Both the necessary adhesion and bonding strength, along with elastomer to plastic overmolding, guarantee that the parts can withstand the operational stresses, which can give them the ability to last long and be reliable.

Versatile Applications

Custom overmold molds are used in a broad array of industries, parts, and materials in automotive overmold tooling, consumer product overmolding, electronics, and medical device tooling.

Overmolding Services at SunOn

We provide a complete variety of custom overmold tooling services at SunOn Mould, which include:

- Complex design Overmold tooling.

- Multi-material part injection moulding tools, Two-shot.

- Prototyping overmold tooling to develop quickly.

- Small and large-volume production of overmold tooling.

OEM/ODM overmold tooling services to client requirements. Our gurus integrate high-technology mold flow analysis of overmolding with new design methodologies such that your gadgets of overmolding give dependable, quality components each and every time.

Technical Know-How in the Excellence of Overmold Tooling

The production of high-precision overmold molds that have to be durable cannot be carried out without sophisticated machinery. It requires in-depth technical expertise and careful planning. The following are the technical areas that we streamline:

Mold Flow and Runner System Design

On the engineering of an over-molding and a runner system, we are able to mold flow uniformly through the use of mold flow analysis that reduces air traps, weld lines, and surface defects.

Optimization of Cooling Channels

Effective design of cooling channels ensures that the temperature in parts remains constant throughout injection, creating shorter cycle times and eliminating warping in multi-material parts.

Gate Design and Tolerance Control

Optimization of the design of gates and extreme control of the tooling tolerance allow placing the material with precise placement, achievements in adhesion between materials, and uniform finishes of the surface.

Choice of Material and Mold Construction

We select mold steels, including H13, S136, or P20, depending on the needs of the parts. Special skill in building molds and cores will guarantee the durability of molds with high-volume production.

Applications

Custom over-mold tooling is utilized in a wide range of industries, and it offers the solution to the parts that need to be precise, durable, and ergonomically designed.

Automotive Industry

In soft-touch grips and dashboard trims, automotive overmold tools create components that are resistant to high wear, vibration, and temperature changes.

Consumer Products

Tooling of consumer products allows ergonomic handles, soft-touch grips, and protective casings, which are more convenient and comfortable.

Electronics

The advantages of overmolded electronics are high-precision overmold tooling, tight tolerances, and dependable insulation of delicate electronic devices.

Medical Devices

Medical overmolding needs molds capable of making sterile, biocompatible parts with high dimensional requirements.

Industrial Equipment

The components of engines and other machinery of industries frequently need shock-resistant or shielded parts that are manufactured with industrial-level overmolding equipment.

Why Should You Use SunOn as a Choice of Custom Over-Mold Tooling?

SunOn is a company that is known as a professional overmold tooling manufacturer, with professional teamwork and customer service. This is the reason we are the preferred partner:

Extremely Precise Tooling- Our molds have very tight tolerances and very smooth finishes.

Multi-Material Expertise - Overmolding of plastic and rubber, TPEs, and elastomers.

Rapid Prototyping - Rapid development of prototypes guarantees rapid development of products.

Global Services - OEM/ODM overmold tooling services in the USA, China, and others.

Sophisticated Processes in Manufacturing - CNC machining, EDM machining, mold assembly, and polishing.

Industry Certifications- ISO 9001:2015, ISO 14001:2015, IATF 16949:2016 compliance.

Rapid Prototyping and Low-Volume Production

In the case of businesses that are developing new products, quick overmold tooling prototyping enables early testing and prototyping of the design. SunOn offers solution flexibility to:

- High-volume overmold tooling manufacturing.

- Design validity and functional testing.

- Rapid changes before full-scale production.

This method saves on the cost, lessens the time of product development, and assures optimal product design functionality prior to investing in large-scale manufacturing.

Conclusion

Modern manufacturing requires the use of custom overmold tooling, which allows production of high-precision multi-material components (automotive, consumer, medical, electronics, and industrial). The technical knowledge, modernized machinery, and innovative design offer overmolding tooling solutions that are beyond the expectations of SunOn Mould.

Do you need a high-precision multi-material overmold tool, soft-touch components that are easy to use, or a large-scale production? SunOn can be your reliable choice in professional overmold tooling services.