Custom Alu Zinc Die Casting Tooling | Precision & Fast Delivery

What is Alu and Zinc Die Casting Tooling?

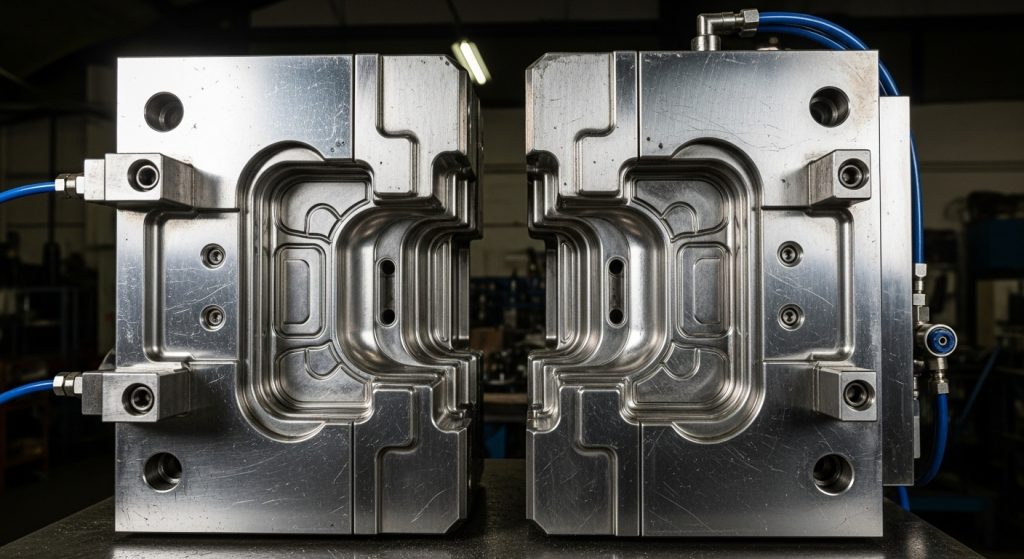

Alu and zinc die casting tooling is a process that produces a mould dedicated to aluminum and zinc alloys. These are precision-engineered molds that are employed in the die casting process, where the molten metal is injected at high pressure into mold cavities.

Key Benefits Include:

- Extremely high dimensional precision with CNC-machined die-cast mold.

- The capacity to develop a multi-cavity die casting mold to produce in large quantities.

- High-cycle production, Excellent tooling performance, and lifetime.

- Mold designing optimization to cool quickly and have low shrinkage.

Production of industrial aluminum and zinc components, automotive parts, consumer electronics housings, and medical device components is best done using the process.

Custom Alu Zinc Die Casting Tooling: Accuracy, Speed, and Dependability

In high-performance manufacturing, the selection of appropriate custom alu zinc die casting tooling is very important in making enduring, accurate, and quality components. The industries in Asia are also depending on the advanced die casting solutions, which are providing them with the complex designs, and an experienced manufacturer of the die casting tooling would be efficient, economical, and consistent. The specialty of SunOn Mould is the custom die casting tools and the aluminum zinc die casting mould that are of the best industry standards.

- From Design to Production

Die casting starts with the optimization of the designs of the molds. Part geometry, thermal flow, and alloy behavior are studied by engineers to produce molds that will guarantee:

- Exact Cavity Size - Parts are subject to high-tolerance requirements.

- Thermal Control - Maximization of cooling channels to achieve consistent solidification.

- Die Casting Shrinkage - Minimizing deformation and warping.

After the design has been finalized, high-precision die casting tooling of aluminum and steel moulds is produced, with CNC machining processes frequently applied to achieve precision.

- During Production:

- High-pressure Molten aluminum or Zinc alloy is forced under high pressure into the mold.

- Solidification is achieved fast, and the quality is constant.

- Particulars are thrown out, pruned, and deburred, and finally used.

This is a managed process that ensures high-speed die casting production, low-volume die casting tooling solutions, and mass production.

Best of Custom Alu Zinc Die Casting Tooling

Making custom alu zinc die casting tooling is associated with several technical and operational benefits:

Precision and Accuracy

- Die casting tools result in high precision, making each component fully specific.

- Multi-cavity die casting molds enable the production of multiple parts at the same time in uniformity.

- The design of the mold cavity reduces the number of defects and enhances flow.

Durability and Performance

- The tooling life and capacity do not wear out easily in case of long production runs.

- Heat and mechanical stability minimize the maintenance requirement and increase the life of tools.

Cost-Efficiency

- Customized molds save on time and material wastage.

- In the long run, good tooling will reduce the per-part cost in mass production.

Diversification in Industries

- Precision alu zinc die casting molds are useful in automotive, consumer electronics, medical devices, and industrial equipment.

- Very complicated forms, detailed products, and final products of aluminum and zinc can be produced easily.

Uses in the Industry

- Automobile Die Casting Parts

The automotive parts demand dimension accuracy, hardness, and uniformity. One of our specialized tools makes engine parts, engine housings, brackets, etc. The fast die casting production means that there is a fast turnaround, and the quality is not affected.

- Consumer Electronics

In the case of electronics, aluminum casting molds are required to be precise in housings, inner frames, and connectors. Rapid prototyping facilities enable the design to be developed and then be produced on a larger scale.

- Medical Device Components

Medical applications require die casting tooling that has tight tolerances and is available in biocompatible materials in low volumes. We have tooling that assists prototypes and parts towards production.

- Industrial Equipment

Machinery, electrical, and equipment components are good candidates for high-cycle die casting, which gives a high level of durability and reliability for industrial use.

Specialization in Custom Die Casting Tooling

At SunOn Mould, we are offering an end-to-end die-cast tooling solution:

Fast Die Casting Tooling Services

- Rapid prototype and small batch manufacturing.

- Express production saves lead times without compromising quality.

Tooling, Prototyping, and Production-Ready

- Low-volume production and high-volume production tooling.

- Checks the consistency of the mechanical parts and makes sure they are fit for the market.

Surfaces, Finishes, and Materials

We deal with aluminum and zinc alloys of high quality that can be used in industries. Our tooling supports:

- Die Casting Mold Manufacturing of Aluminum - An industrial, strong, and light framework.

- Zinc Alloy Die Casting Tooling - Corrosive components that are highly detailed.

- Surface Finishes - Finishes may be polished, textured, anodized, or custom to suit the design needs.

Such materials and finishes guarantee the use of industrial aluminum and zinc materials to achieve functionality and aesthetics.

Why Choose SunOn Mould?

- Technical Expertise - Decades of experience in die casting tooling of high precision.

- Quick Turnaround - Quick manufacturing of moulds keeps the projects on track.

- State of the Art - CNC-machined die casting molds, multi-cavity die casting molds, automated die casting processes.

- Quality Assurance -All molds are carefully checked to ensure that the tooling can last and work.

- International Expansion - Reliable Asian die casting tools suppliers in the automotive, electronics, medical, and industrial industries.

SunOn Mould combines innovation, accuracy, and speed in order to provide the most optimal custom alu zinc die casting tooling solutions.

Conclusion

The custom alu zinc die casting tooling is important because it is needed by the manufacturers who want to achieve precision, speed, and cost efficiency. SunOn Mould offers high-precision molds, multi-cavity production, and thermal control optimization to help automotive, consumer electronics, medical, and industrial customers find fast, reliable, and scalable solutions in die casting.