Automotive Alu Zinc Die Casting Mold | Precision Casting

What is an Automotive Alu Zinc Die Casting Mold?

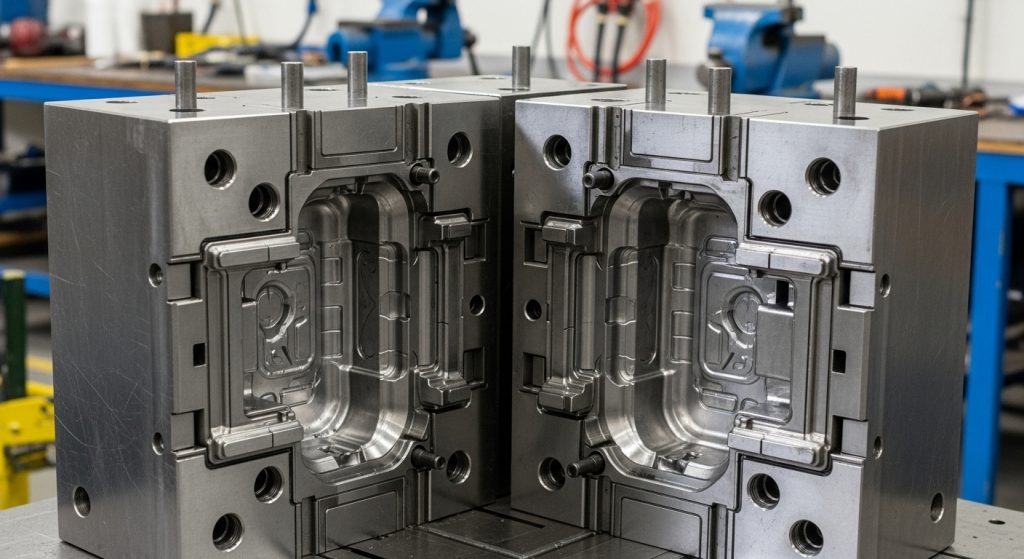

Automobile aluminum zinc die casting mold is a die-casting instrument that is applied to manufacture aluminum and zinc alloy parts of high precision via high-pressure die casting. An injection of molten Al-Zn alloys into specially crafted molds is done to create parts of precise dimensions, smooth surface finishes, and good structural stability.

Key Advantages:

- Dimensional precision of 0.05 mm, which guarantees a flawless fit in assembly.

- The capacity to form complicated geometry molds, which hold complicated engine parts and structures.

- Long-life span molds that can handle large volume production cycles.

- Recrystallization of Al-Zn alloys to homogenous solidification.

Die Casting Technology of High Precision

In modern automotive die casting, CNC-machined die molds, hot and cold chamber die casting, and advanced mold flow analysis are used to provide excellent quality of parts.

Die Casting Hot Chamber Vs Cold Chamber

Hot chamber die casting molds are best used with zinc-rich alloys, and it has a rapid cycle time and good finish.

The Cold chamber die casting molds are used in operating aluminum-heavy alloys and have the capacity of injecting high-temperature melts.

Multi-Cavity Die Casting Molds

In multi-cavity molds, manufacturers will be able to inject multiple parts in one mold injection. This enhances efficiency in production, cycle time, and quality consistency of all the components.

Thermal Control & Mold Flow

Adequate temperature regulation guarantees even solidification of alloys. Mold flow analysis is used to avoid defects, including porosity, warping, and surface defects.

Excellence in Materials and Manufacturing

The automotive die casting molds are produced to suit performance criteria using a certain material. Some of the commonly used alloys are:

Aluminum-Zinc Alloys (Al-Zn) - Lightweight, high-strength, and non-corrosive.

Automotive Grade Aluminum - Suits best where it is used in engine parts and structural parts.

Zinc Die Casting - Offers high levels of dimensional integrity of small complex components.

The other factors to be considered in choosing the material are thermal stability, wear resistance, and compatibility with surface finishing methods such as polishing, anodizing, or coating.

Design Engineering Innovations

Automotive Al-Zn die casting molds need precision engineering in their design.

Custom Die Mold Design

- Customized to engine parts, transmission parts, car body, and automotive hardware for consumers.

- Modeling 3D CAD die moulds is used to make each mold flow optimally, cooled, and solid.

- Develops prototypes to production changes with ease.

- Accuracy and Stasis subject.

- Dual-strength molding components are stable with high-pressure repetitive cycles.

- Intricate geometry molding enables the manufacturing of complex automotive components without them being of low quality.

Assures surface finish Ra 0.8-1.2 mm of both practical and decorative needs.

Automotive Usage of Alu Zinc Die Casting Molds

Die casting aluminum and zinc alloys molds have been employed in the automotive industry to give light and strong parts. Common applications are:

- Housing, covers, and manifolds. Engine parts.

- Transmission elements: Gear housings, brackets, and support structures.

- Structural elements of the car body - lightweight frames and reinforcements.

- Consumer automotive hardware - automotive handles, knobs, and decoration.

- Enclosures of industrial machinery and electronics - automotive levels of reliability and accuracy.

All the applications have the advantage of high-volume die casting manufacturing, quick prototyping die cast moulds, and accuracy in mold design of aluminum zinc alloy die castings.

The Quality Assurance and Standards

In automotive die casting, quality is the most important. At Sunon Mould, molds are strictly put under quality control:

- Die-cast molds are ISO-certified and ensure compliance in the industry.

- During tolerance verification, dimensional requirements are ensured.

- Mold testing performance is checked on durability and repeatability by testing thousands of cycles.

- Surface finish optimization provides zero defective components that have a high aesthetic quality.

This demands a high level of scrutiny so that the high-volume automotive die casting molds will always produce high-quality parts regardless of the application.

Recompense and Productivity Benefits

There are many efficiency benefits in investment in automotive Al-Zn die casting molds:

- It is the production of high-speed die castings that shortens the cycle times and boosts the throughput.

- Multi-cavity productivity optimization enables two or more components to be produced at the same time.

- The low-waste casting process reduces the use of material and the cost of production.

- New automotive designs can be delivered to the market very fast with fast lead-time die casting mold production.

- With mold optimization, it is the engineering that ensures that the molds are not only performance-optimized but also durable.

These benefits render aluminum zinc die-cast molds a perfect choice in the manufacturing of vehicles, as it is fast, precise, and economical.

Business and Purchase-Intent Advantages

By making Sunon Mould your automotive die casting mold manufacturer:

- Die casting mold supplier of custom aluminum zinc die casting molds of any specifications.

- OEM die casting mould solution for auto manufacturers.

- Die casts low or high volumes to suit project volumes.

- One-stop automotive die casting moulding, concept to mass.

- Aluminum zinc casting solutions are cost-effective in terms of reducing the cost of production.

Die Casting Molding supplier with assured quality and reliability of parts.

Die Casting Trends in the Future of the Automobile Industry

The automotive business is now moving towards lightweight and high-strength parts; therefore, aluminum zinc die casting molds have become unavoidable. Emerging trends include:

- High-end molding materials are to have a longer life cycle and higher thermal performance.

- Mold design based on simulation by the use of mold flow and stress analysis software.

- Hybrid prototyping and tools: Hybrid prototyping and tooling with integration with additive manufacturing.

Reduction of waste and consumption of energy in the die casting operations through sustainability practices.

These inventions can enable automotive companies to produce tough, easy, and efficient cars at a reasonable cost and accuracy.

Conclusion

An automotive alu zinc die casting mold is necessary in the fabrication of high-quality, durable, and complex automotive parts. These molds are used in engine components, structural components, as well as automotive hardware utilized by the consumer goods, and offer high precision, structural stability, and high mass production features.

We have designed SunOn Mould with a mix of professional designing of molds, CNC machining, mold flow analysis, and high-quality control to provide custom molds of aluminum zinc die casting to both low-volume and high-volume automobile manufacturing. We are efficient, precise, and reliable, so that each mold supports the high requirements of the automotive industry to allow our clients to attain a lower cost of production, short lead times, and high performance of the parts.