2K Injection Mould (Dual Color Injection) | Precision Two-Shot Moulding

What is a 2K Injection Mould (Dual Color Injection)?

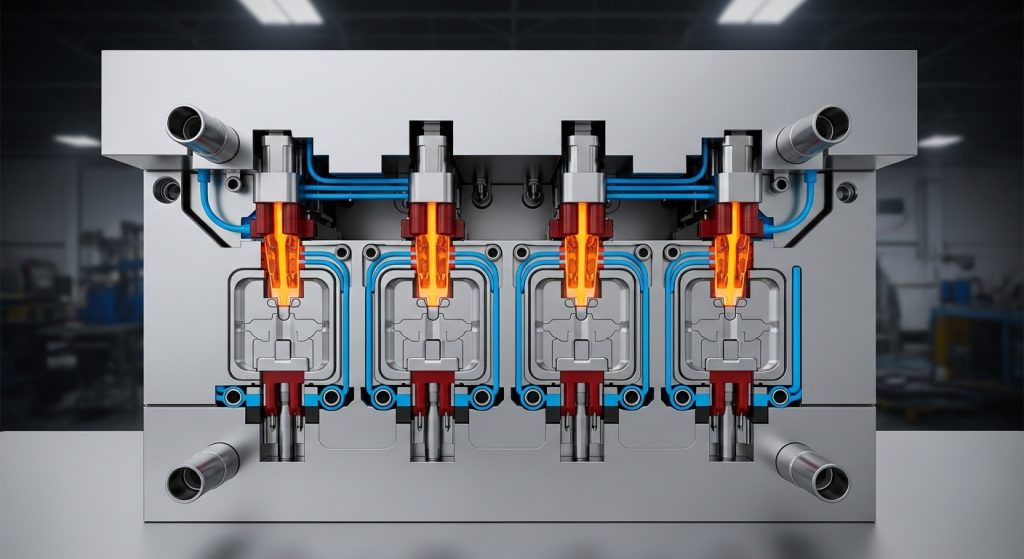

A 2K injection mould is a specialised tool used with two-component (2C) injection moulding, whereby 2 different materials or colours are injected into the same mold cavity in a series. This process forms a single component with more than one material, frequently that of soft-touch grips and hard plastic bottoms, or contrasting colours to be visually attractive.

Important Characteristics 2K Injection Moulds

- Seamless bonding technology is also applied to make sure that materials blend well.

- Two-cavity and rotary cores may facilitate materials sequential injection.

- The possibilities of combining various materials, such as TPU+ABS, PC+PC, and soft+hard plastics, are enabled by material compatibility.

- Applicable in other uses such as two-color logos, seals, ergonomic grips, and medical parts.

The 2K Injection Moulding Process

The injection moulding process in 2K is very technical and accurate, and needs experience in CAD designing, precision machining, testing of the moulds, and production of the moulds in large numbers. Here's how it works:

CAD Design

Engineers develop dual-cavity molds by using a sophisticated CAD program to have rotating cores enabling sequential injection of the molds. This is to make sure that there is accurate alignment and optimum flow of the two materials.

Precision Machining

Mold parts with strict tolerances of IN +-0.05 mm are produced using CNC machining, EDM, and polishing. This will provide high-quality final parts, correct cavities, and smooth surfaces.

Mold Testing

Preliminary injection testing is used to ensure the performance of the mold, detect defects, and determine the optimal cycle time to conduct effective production. The use of Mould flow is common to guarantee the correct distribution of materials and prevent sink marks or air traps.

Mass Production

On validation, the moulds can proceed to stable mass production, where they provide high-volume 2K injection moulding with a uniform quality. Quality inspection guidelines and ISO-certified standards are encompassed within our workflow to ensure high standards in each and every batch.

The Technical Benefits of 2K Injection Moulds

The injection mould in 2K has great advantages over the mold in a single material:

Complicated Geometry Shaping - Facilitates multifunctional and ergonomic designs.

Soft-Touch Overmoulding - Hard and soft plastics are used in one component.

Multi-Material Injection Moulding - Improves the durability and product appearance.

Tolerance -0.05 mm - Dimensional accuracy in even complex components.

High-Speed Two-Shot Injection - Cuts down the cycle time and boosts productivity.

Moulding Process with Low Level of Waste - Environmentally friendly and cost-effective.

Such merits render 2K injection moulding suitable for personalized two-color injection moulding in consumer electronics, automotive, medical equipment, and industrial components.

Materials & Applications

Materials

We have 2K injection moulds available in a large variety of thermoplastics and elastomers:

ABS, PC, POM, TPU - Standard plastics of durable parts.

Soft + Hard Plastics- To have an ergonomic design and touch features.

Plastic-Metal Hybrid- Overmoulded - Integrates appearance and functionality.

TPE Elastomers - Ideal in the case of flexible or soft-touch parts.

Applications

Automotive - Auto buttons, grip, dashboards, two-colour exterior.

Medical Devices: Syringes, surgical instruments, dual-material housings.

Consumer Electronics- Cases, control knobs, wearable parts.

Home Appliances and Sportswear - Beautiful, practical, and durable components.

Industrial Machinery- Custom mechanical parts that need dual material properties.

Design Excellence and Engineering Excellence

In Sunon Mould, 2K type mould design is the specialisation of our engineers, which utilises 3D CAD modelling, multi-cavity design, as well as prototype-to-production processes. Key considerations include:

- Seamless interfaces of high precision and dual-colour parts.

- Ergonomic and functional hard-soft overmoulding.

- Tight-tolerance part dimensional accuracy +-0.05 mm.

- Dual colour injection stack moulds to enhance production efficiency.

We achieve precision of overmoulded parts and minimise material defects through precision engineering and guarantee consistency in quality within each production cycle.

Performance & Efficiency

2K injection moulding is developed with maximum efficiency:

- There are rapid cycle 2K injection moulds that permit more rapid throughput.

- The Multi-cavity productivity optimization will guarantee that there are various parts in a single cycle.

- Quick 2K mould production: 2K moulds can be produced quickly to meet urgent project deadlines.

- Mould solutions that are engineering-driven offer high-volume or low-volume cost-effective solutions.

We minimize the cost of production and ensure high-quality performance and cycle time through optimization of mould designs, the cycle time, and the flow of materials.

Quality Assurance & Standards

All 2K injection moulds are done to strict quality and ISO-certified standards:

- Checking of dimensional accuracy is done by tolerance.

- Surface finish Ra 0.8-1.2 mm, high-quality appearance.

- The performance testing of moulds proves the efficiency of the cycles and the quality of parts.

- Regularity of production in small and large volume orders.

Such steps will ensure that the accuracy of 2K injection moulds is able to provide a stable operation regardless of the purpose.

Commercial Advantages

There are unique commercial advantages of selecting Sunon Mould for 2K injection moulding:

Small Parts, Custom Dual-Colour Injection Mould Manufacturer - Solutions to individual projects.

Acceptance Test, Rapid Prototyping - Dual-shot mould - Test designs early before full production.

2K Mould Production- Low Volumes - Best suited to start-ups or batch customisation.

Turnkey 2K Injection Mould- One workflow: design to mass production.

OEM 2k Injection Mould Solutions - Industrial moulds of high quality for the industrial partners.

Dual-Material Moulding That is Cost-Effective - Waste has been minimized, costs are reduced, and delivery is quick.

Conclusion

The 2K injection mould (dual color injection) technology is innovative in plastic production as it allows the manufacture of multi-material and dual-colour, as well as high-precision components. We have a wide range of skills at SunOn Mould in custom 2K mould design, precision machining, mould testing, and production in large quantities, which makes us the company of choice in the automotive, medical, consumer electronics, and industrial machinery industries. We can provide cost-effective high quality dual colour parts of high quality using rapid cycle 2K injection moulds, using advanced materials, and using strict quality standards, and it is able to give a consistent performance.